Made in USA vs. Assembled in USA vs. Berry Amendment | Compliance Guide for Armor Manufacturers

In today’s global defense and safety markets, few issues cause more confusion—or risk—than origin claims. For body armor manufacturers, nylon gear suppliers, or ballistic plate producers, labeling your products correctly isn’t just a marketing tactic—it’s a regulatory minefield.

The terms “Made in USA,” “Assembled in USA,” and Berry Amendment compliance each carry very different thresholds, and missteps can mean FTC investigations, contract disqualification, or loss of credibility with agency buyers. At IntelAlytic, we combine compliance consulting with the unmatched data of The Armor List to give manufacturers and procurement teams a clear playbook for navigating these rules.

This guide breaks down each category with 100% factual clarity, citing FTC guidance, DoD Berry Amendment requirements, and compliance risks specific to ballistic-resistant products.

What Does "Made in USA" Really Mean?

The Federal Trade Commission (FTC) strictly regulates unqualified “Made in USA” claims. To qualify, a product must be “all or virtually all” made domestically. That means:

Final assembly or processing occurs in the U.S.

Nearly all significant components and labor are U.S.-sourced.

Any foreign content must be negligible.

Example for the armor industry: If your soft armor vest uses imported UHMWPE fabric but is stitched in North Carolina, it does not qualify as “Made in USA.” Even small percentages of imported ballistic fabric or thread can invalidate the claim.

FTC Guidance Link: FTC: Complying with the Made in USA Standard

Enforcement Trend: In 2025, the FTC penalized several companies for falsely labeling imported-heavy tactical goods as U.S.-made. The risk isn’t theoretical—civil penalties under the FTC Act can exceed $40,000 per violation.

Quick Fact Check: If your bill of materials shows even 10% imported by cost, you’re almost certainly outside FTC’s “virtually all” threshold.

"Assembled in USA": A Loophole—But with Limits

Unlike “Made in USA,” the “Assembled in USA” claim has no requirement for domestic parts or raw materials. All components can be imported—as long as the final assembly is performed in the United States and is deemed “substantial.”

What counts as substantial? According to the FTC, the assembly must be more than “minimal finishing,” such as:

Attaching a label

Packaging

Adding a coating or finish

Example: If imported ballistic plates are merely inserted into a carrier and packaged in the U.S., that is not substantial assembly. But if imported aramid rolls are cut, layered, and stitched into panels in the U.S., the “Assembled in USA” claim may apply.

FTC Reference: FTC Policy on Assembled in USA Claims

Common Pitfall: Many armor companies misuse this claim, implying domestic origin when all ballistic fabrics, ceramics, or nylons are foreign. The FTC considers this deceptive marketing.

Pro Tip for Transparency: Use qualified language like:

“Assembled in the USA with imported ballistic fabrics and global components.”

This honesty builds trust with buyers and sidesteps enforcement risk.

Berry Amendment Compliance: DoD’s Zero-Foreign Tolerance

If you supply to the U.S. Department of Defense, the rules are stricter. The Berry Amendment (10 U.S.C. § 4862) requires certain items procured with DoD funds to be 100% U.S.-sourced, processed, and manufactured.

Covered categories include:

Textiles & Clothing: body armor carriers, soft armor panels, uniforms, helmets, tents

Specialty Metals: armor steel, titanium, stainless components in armor plates or buckles

Food & Hand Tools: less relevant to armor, but part of Berry’s scope

For body armor, this means:

Aramid and UHMWPE fibers must be spun and woven in the U.S.

Nylon fabrics, thread, and hook-and-loop tape must be U.S.-origin.

Armor steel for hard plates must be melted/rolled in the U.S.

Exceptions? Only via DoD-issued non-availability waivers, typically for urgent needs.

Reference: DoD Berry Amendment Overview – Defense Logistics Agency

Critical Difference:

FTC’s “Made in USA” allows “virtually all.”

Berry requires 100% domestic for covered items.

Violations can trigger contract termination and future ineligibility.

Ballistic-Resistant Materials: Berry Coverage Reference

Berry Amendment Coverage Table (Table 1)

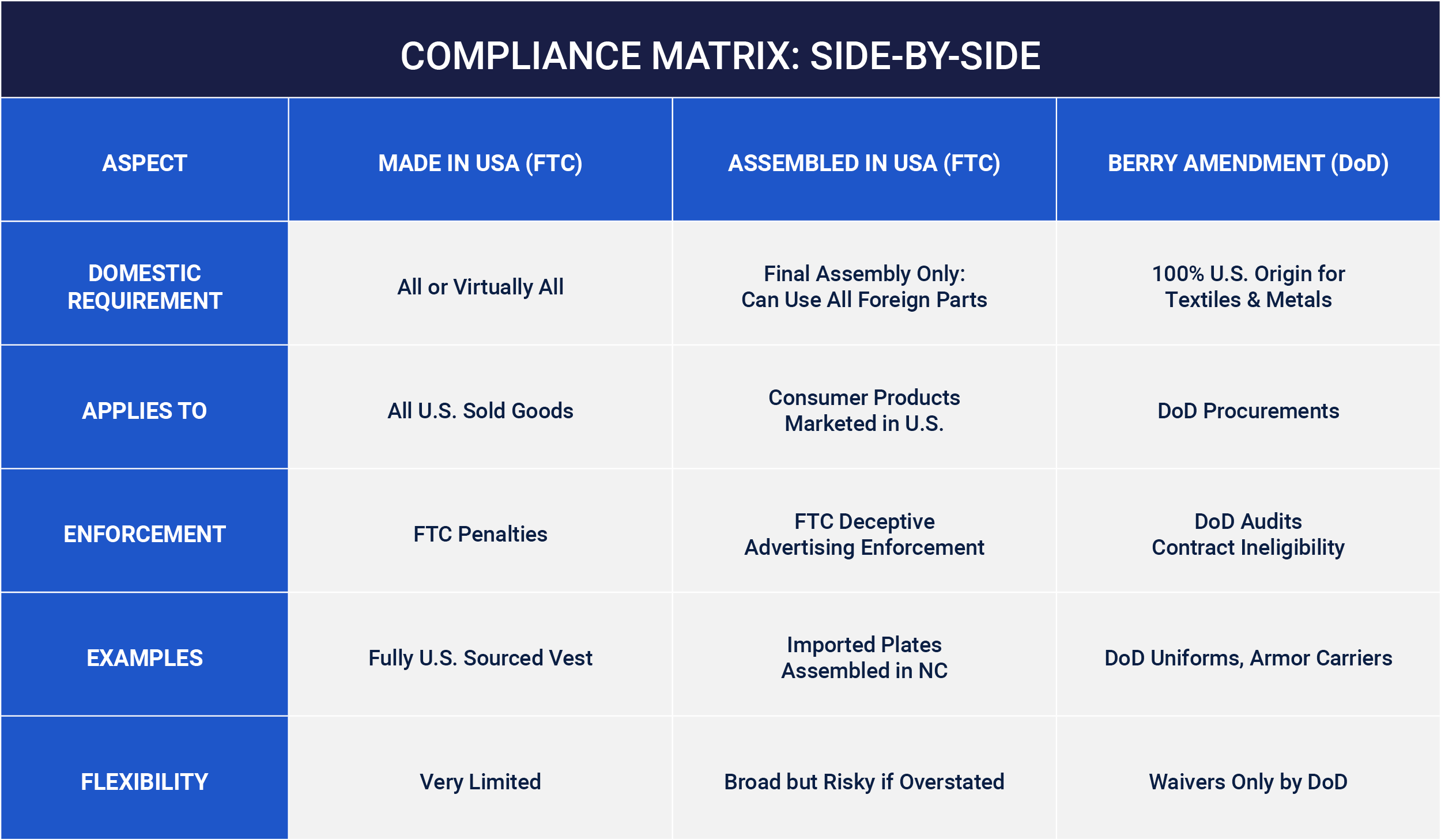

Compliance Matrix: Side-by-Side

Made in USA vs. Assembled in USA vs. Berry Compliant Matrix Table (Table 2)

Compliance Tips for Body Armor Manufacturers

Document Everything: Keep supplier certifications, bills of materials, and fiber traceability records.

Use Verified Data: Platforms like The Armor List provide 250,000+ verified entries on body armor products, materials, and certifications.

Train Marketing Teams: Ensure product claims reflect FTC and Berry standards—mislabeling armor can destroy brand trust.

Audit Supply Chains: IntelAlytic’s consulting team conducts origin and compliance audits specifically for ballistic-resistant products.

Seek Waivers Wisely: If sourcing challenges arise, apply for Berry exemptions early through the DLA.

Quick Interactive Quiz

-

Answer: No, the foreign ballistic fabric disqualifies it.

-

Answer: Yes, as long as assembly is substantial (cutting, layering, bonding).

-

Answer: Yes, Berry requires U.S. origin for all textiles

Final Word: Compliance = Competitive Advantage

The fragmented world of ballistic protection is full of misleading claims. Manufacturers who can prove compliance—whether FTC “Made in USA” claims for retail or Berry Amendment sourcing for DoD—hold a competitive edge.

At IntelAlytic, we don’t just analyze—we connect the dots:

Consulting expertise in FTC, NIJ, ITAR/DFARS compliance.

The Armor List is the single-source database for products, certifications, and sourcing.

Want your brand recognized as a trusted, compliant supplier? Feature your company with a sponsored post on The Armor List—reaching agencies, OEM integrators, and tactical buyers worldwide.

Learn More: armorlist.com/advertising or email support@intelalytic.com

Sources: FTC, DoD / Defense Logistics Agency, International Trade Administration.