Understanding Ballistic Test Lab Reports: What to Look For in Supplier's Data

In personal protective equipment, particularly body armor, the integrity and reliability of products are crucial—they are the difference between life and death. Ballistic test lab reports are the cornerstone of product evaluation, providing insights into a product's resilience against ballistic impacts under controlled conditions. As an industry expert, I have seen firsthand how a deep understanding of these reports can transform operations in the field. This article aims to guide manufacturers, suppliers, and end-users through the complexities of ballistic test reports, fostering a comprehensive understanding of each critical element.

Understanding Ballistic Testing

Ballistic testing is a rigorous and indispensable process in developing and certifying body armor and other protective materials. This testing rigorously subjects materials to controlled projectile impacts, reflecting the real-world threats that wearers might face, whether in law enforcement, military engagements, or personal protection scenarios. The primary goals of ballistic testing are twofold: firstly, to evaluate the material's effectiveness in preventing penetration from bullets, shrapnel, or other projectile threats; secondly, to assess its ability to minimize blunt force trauma.

Blunt force trauma is a critical safety concern, referring to the energy transferred through armor even when no penetration occurs. This energy can cause severe bruising, internal injuries, or even fatal harm, underscoring the importance of both stopping bullets and mitigating the force transmitted to the wearer. Thus, understanding and improving these protective aspects are as crucial as the armor's ability to thwart penetration.

The Testing Process

The ballistic testing process follows several standardized steps to ensure consistency and replicability:

Preparation of Test Materials: Body armor or protective fabric samples are prepared to meet specific guidelines that include their dimensions, conditioning, and how they are mounted on test forms that simulate human wear. This step is crucial for ensuring that the testing reflects real-world conditions as closely as possible.

Selection of Ammunition: The ammunition used in testing is carefully chosen based on the threat levels the armor is designed to withstand. Depending on the armor's specifications, this selection can vary from handgun rounds to high-caliber rifle bullets.

Controlled Test Firing: Ammunition is fired at armor samples from fixed distances, precisely aiming to achieve consistent impact points and reliable test results. The velocity of each projectile is also rigorously monitored to maintain the integrity of the test.

Measurement of Penetration and Backface Deformation: The armor is examined for penetration after firing. Impacts that do not penetrate are further analyzed to measure backface deformation—the dent on the clay or other backing materials used to simulate human tissue. This critical measurement indicates the potential blunt force trauma that could be transferred to the wearer.

Data Analysis and Reporting: The results are meticulously recorded, with detailed analyses of the material’s performance and any failures during the test. This data is vital as it forms the core of the ballistic test lab report, detailing whether the armor met the required standards and was performed under various conditions.

Importance of Standardization in Testing

Ballistic testing adheres to stringent standards set by authoritative bodies like the National Institute of Justice (NIJ) in the United States to ensure that all body armor meets minimum safety requirements. These standards specify the types of weapons and ammunition for testing and define the environmental conditions under which the tests must be conducted. Strict compliance with these standards is essential to guarantee that all tested armor provides reliable protection.

Comprehensive Elements of a Ballistic Test Report

A ballistic test report is not just documentation—it narrates the story of the test, instilling confidence in the body armor's performance. To ensure a report's completeness and reliability, the following components must be thoroughly scrutinized:

Reference: National Institute of Justice, NIJ Standard 0108.01: Ballistic Resistance Test Variables and Test Requirements

General Information: Includes the model name and description, sizes and weights, serial and lot numbers, and other identifiers that ensure traceability.

Test Summary: This summary captures the objective, date, and location of the test, setting the context for the evaluation.

Material Description: Provides details about the materials used, including the layers of fabric, composite structures, and any unique treatments or technologies applied.

Test Methodology: Outlines the standards followed, the types of projectiles used, and the distances from which they were fired, ensuring adherence to established protocols.

Detailed Results: Records incidents of penetration and non-penetration, measures of backface deformation, and any failure points observed during the testing.

Quality Control Measures: Examine the samples' consistency and the environmental conditions maintained throughout the testing process.

Special Notes: This section includes any modifications to standard testing protocols and the justifications for these changes, providing transparency.

Expert Analysis: What to Look For in Supplier's Data

When reviewing a supplier’s ballistic test data, a critical and analytical approach is essential:

Compliance and Standards: Confirm that the testing strictly meets recognized standards. Deviations from these standards are significant red flags.

Detail and Clarity: The report should be devoid of any ambiguity. Precise, detailed descriptions and presented results indicate a meticulous approach to testing.

Independence of Testing: Testing should be conducted by an accredited independent laboratory to avoid bias and ensure reliable and impartial results.

Recent and Relevant Testing: The data should be current and align with the latest standards and threats to ensure the armor's ongoing relevance and effectiveness.

The 7 Key Red Flags to Look Out for When Reviewing a Ballistic Test Report

Identifying potential issues in ballistic test reports is critical for ensuring the reliability and safety of body armor. Be vigilant for these seven red flags, which may indicate deficiencies or discrepancies in the testing process:

Non-Compliance with Standards: Any deviation from established testing standards such as NIJ or MIL-STD signals a significant concern. Compliance is crucial as it ensures that body armor is evaluated against rigorous and accepted criteria, which is essential for ensuring protective performance.

Inconsistencies in Data: Variations in results under similar test conditions or discrepancies noted within the report may indicate problems with the armor's reliability or flaws in the test methodology.

Outdated Testing Methods: Testing protocols that do not account for current ballistic threat levels or newer armor technologies can render the results obsolete and irrelevant for modern applications.

Incomplete or Missing Documentation: A comprehensive report should include all relevant details, including test methodologies, ammunition specifications, and environmental conditions. Gaps in these areas, such as a missing cover letter or incomplete results, undermine the report's completeness and integrity.

Signs of Document Tampering: Any indications of modifications, such as inconsistencies in fonts, layout discrepancies, or signs of cut-and-paste in digital files, are serious red flags. These suggest potential tampering and doubt the data's authenticity and reliability.

Unaccredited Testing Facilities: The credibility of the testing facility is essential. Testing performed at facilities lacking accreditation from recognized bodies does not assure quality and unbiased results.

Lack of Independent Verification: A test report lacks an essential layer of credibility without peer review or independent verification. Independent checks are crucial for adding transparency and objectivity to the testing process.

Recognizing these red flags is vital for assessing the quality and reliability of ballistic test reports. Accurate and thorough testing is not merely a regulatory compliance issue but a fundamental measure to safeguard lives. As industry experts, we must uphold the highest standards of transparency and integrity in all testing procedures.

Evaluating Ballistic Test Results: Internal Labs vs. Accredited Independent Laboratories

Understanding the difference between internal company-owned laboratories and accredited independent facilities is crucial when assessing the reliability and accuracy of ballistic test results.

Internal Company-Owned Laboratories:

These facilities are integral for research and development, quality control, and ongoing lot testing. They enable companies to refine and validate their products continuously before market release. Utilizing in-house labs for iterative testing and product development is standard practice, providing immediate data and feedback that facilitate rapid product improvements. However, internal testing, while critical for maintaining product standards and consistency, may carry inherent biases.

Sole reliance on data from a company's lab to benchmark product performance poses risks. The absence of external oversight can lead to potential conflicts of interest or unconscious biases in result reporting. Consequently, while internal test results are invaluable for development and internal assessments, they are not the sole evidence of product performance concerning safety standards and certification.

Accredited Independent Laboratories:

In contrast, accredited independent laboratories deliver an essential level of objectivity and standardization for certifying protective gear. These laboratories operate independently from manufacturing entities, ensuring that evaluations are impartial and based solely on the product's performance against established standards. Accreditation signifies adherence to rigorous operational and ethical standards, enhancing the credibility of the testing process.

Manufacturers, suppliers, and end-users must depend on results from accredited independent laboratories. This practice ensures compliance with industry standards and bolsters confidence in the product’s efficacy under real-world conditions. Independent testing serves as a critical verification step, affirming the integrity and safety of the product.

While internal laboratories significantly contribute to the research, development, and quality control of body armor, definitive validation of product performance must come from accredited independent labs. This approach guarantees that protective gear meets the highest reliability and safety standards, providing robust, impartial evidence of effectiveness to customers and regulatory bodies.

Conclusion

Ballistic test lab reports are crucial components of the safety assurance process in the body armor industry. Thoroughly understanding every aspect of these reports is essential for manufacturers, suppliers, and end-users to ensure that the body armor performs as certified, providing maximum protection when it is most needed. As industry experts, we must insist on rigor, transparency, and strict compliance to guarantee that protective gear fulfills its life-saving potential.

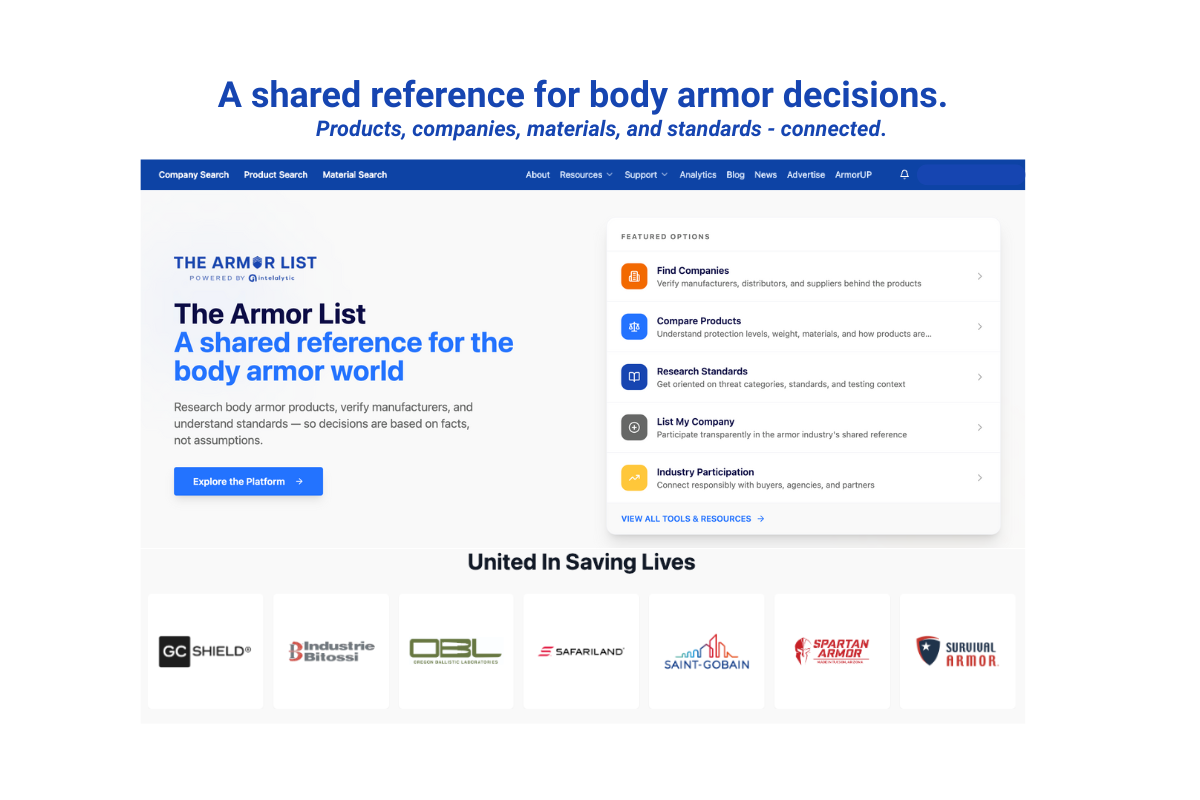

For entities aiming to elevate their capabilities in the ballistic-resistant materials sector, IntelAlytic offers a comprehensive array of professional services. Our expertise spans engineering, design, manufacturing, and more, assisting industry partners in surpassing the demands of testing, compliance, and certification. IntelAlytic provides access to advanced technology resources and a network of expertise supporting every phase of the lifecycle—from concept to delivery.

Embrace the future of safety and innovation. Let IntelAlytic guide you through the complexities of industry standards and help you achieve excellence in every product. Reach out today to discover how our insights and services can empower your operations and ensure your protective gear stands the test of time and challenge.

Bonus

Here is a selection of 20 essential terms that are particularly relevant and beneficial for understanding the critical aspects of ballistic material testing and body armor:

Accreditation: Recognition that a testing facility meets specific standards and operates under industry-approved conditions.

Angle of Incidence: The angle at which a projectile strikes the armor, affecting how the armor disperses the impact's energy.

Armor Piercing (AP): Ammunition designed to penetrate protective gear, often made with a hardened core.

ASTM: American Society for Testing and Materials, developing standards for material testing, including body armor.

Backface Deformation (BFD): The indentation on the armor's non-threat side, indicating potential blunt force trauma.

Ballistic Limit: The maximum projectile velocity that a specific type of armor can reliably stop without penetration.

Ballistic Testing: Evaluation of protective materials against controlled projectile impacts to simulate real-world threats.

Caliber: Measurement of a bullet's diameter, critical in defining ammunition specifications and compatibility with firearms.

Composite Armor: Protective gear from multiple material layers enhances threat resistance.

Edge Strike: Occurs when a projectile impacts the very edge of an armor plate, which can affect the armor's performance.

Fragment Simulating Projectile (FSP): Standardized projectiles used in testing to simulate shrapnel and fragmentation threats.

Multi-Hit Capability: Refers to an armor's ability to withstand impacts from multiple projectiles.

NIJ Standards: Guidelines set by the National Institute of Justice for body armor performance.

Penetrator: Hard core within a bullet designed to improve penetration through armor or hard targets.

Quality Control: Processes to ensure products meet specified standards consistently throughout production.

Spall Liner: An additional layer in armor systems designed to catch spalling or fragmentation from the impact of a projectile.

Terminal Ballistics: is the study of a projectile's behavior and effects upon impact with a target, which is crucial for understanding armor performance.

Trauma Pad: A pad placed behind armor plates to mitigate backface deformation and reduce the force transferred to the wearer.

V0: The maximum velocity at which no projectiles penetrate the armor during any test, indicating the absolute protective capability of the armor under specified conditions.

V50: A statistical measure used in ballistic testing to determine the velocity at which a projectile has a 50% chance of penetrating a given armor material, providing a benchmark for the armor's effectiveness.

Interested in working with IntelAlytic?

Explore IntelAlytic Services

Follow us on LinkedIn for daily tips and resources