Precision in Practice: Optimizing Documentation and Data Tracking for Body Armor R&D

Why Documentation and Data Tracking Are Critical in Armor Development

In the body armor industry, robust documentation and data tracking are essential for regulatory compliance, quality assurance, risk mitigation, and long-term credibility. Every stage—from material sourcing to ballistic testing and post-certification monitoring—generates critical data that must be traceable, verifiable, and securely managed.

For manufacturers adhering to standards like NIJ 0101.07 (the current ballistic resistance standard as of 2025, superseding NIJ 0101.06), ISO 9001:2015, and BA 9000 (body armor-specific QMS), documentation serves as irrefutable proof of performance and process integrity. Poor management can lead to certification delays, audit failures, legal liabilities, or removal from the NIJ Compliant Products List (CPL).

A structured, closed-loop system not only ensures compliance but also enhances efficiency, reduces errors, and supports innovation. For small companies, this means leveraging simple, cost-effective tools to avoid overwhelming overhead. For large organizations, it involves scalable enterprise systems for cross-departmental collaboration and global operations. Regardless of size, focus on accessibility, security, and retention to protect intellectual property, meet export controls (ITAR/EAR), and safeguard end-users who depend on reliable armor.

Enhanced Documentation and Data Tracking Lifecycle Framework

The following seven-step framework outlines how armor manufacturers can operationalize data discipline across R&D — ensuring every document, test, and change record is traceable, compliant, and audit-ready.

1. Define the R&D Documentation Framework

Start by creating a comprehensive plan before R&D commences. Outline document types, ownership, approval processes, and retention policies.

Key document categories:

Material Technical Data Sheets (TDS) and Safety Data Sheets (SDS)

Ballistic design drawings, assembly specs, and CAD files

Lot-control, material batch, and supplier certification records

Test plans, protocols, and risk assessments

Change-control logs and engineering revision histories

Assign unique identifiers (e.g., DOC-ARMOR-001), revision codes, and multi-level approvals. Use a central Document Control Register to track status, versions, and expiration dates.

For small companies: Use affordable tools (Google Workspace, Microsoft OneDrive) with shared folders and version history.

For large companies: Integrate PLM systems like Siemens Teamcenter for workflow automation and ERP integration.

Retention insight: Maintain NIJ-related records for up to 10 years post-certification (or longer if under legal hold). Plan for hybrid storage, digital and physical.

2. Establish Data Capture Points Throughout R&D

Capture data at every key milestone to ensure completeness and traceability, reducing disputes in audits or claims.

Core capture points include:

Material verification: Supplier certs, fiber specs, batch codes

Armor assembly: Layer configs, adhesives, stitching details

Ballistic testing: Caliber, velocity, spacing, deformation, conditioning (temperature/humidity)

Post-test analysis: V0/V50 results, failure modes, degradation

Link all data to specific lots, revisions, and personnel via timestamps and digital logs.

For smaller firms: Use structured spreadsheets with locked cells.

For larger ones: Implement Laboratory Information Management Systems (LIMS).

Add error-proofing—automated data validation or cross-referencing fields to avoid test inconsistencies that could invalidate NIJ submissions.

3. Apply Version Control and Revision Management

Treat documents as living assets with complete change history and audit traceability.

Best practices:

Use alphanumeric revision codes (e.g., 1.0, 1.1) with author/date logs

Maintain detailed change logs for compliance impact tracking

Implement e-signature workflows (e.g., 21 CFR Part 11 compliant)

Archive old versions in read-only formats

Tools: Small teams may use Git or shared drives; large firms, Autodesk Vault or Arena PLM.

Train staff on versioning rules to ensure uniform document governance.

4. Link Documentation to Testing and Certification

Ensure R&D outputs seamlessly connect to certification submissions.

Maintain:

Test reports tied to drawings and material lots

Certification dossiers with complete evidence

Engineering Change Notices (ECNs) assessing compliance impact

Legal insight: Document discrepancies can result in NIJ revocation or product liability exposure.

International note: Include ITAR/EAR export control statements in all related documentation.

5. Implement Controlled Storage and Secure Access

Protect integrity and accessibility of documentation and data through secure storage.

Practices:

Role-based, encrypted access (AES-256 or higher)

Read-only archives for certified records

Regular, offsite or cloud backups (AWS S3, Azure, or hybrid servers)

Logical folder architecture:

R&D > Materials > Designs > Testing > Certifications

Test recovery quarterly and maintain disaster recovery protocols. Cloud scalability can help smaller companies remain cost-efficient.

6. Extend Data Tracking Beyond Certification

Compliance does not end with NIJ approval—ongoing traceability supports post-market surveillance.

Include:

Serial number mapping to design and material batches

Periodic follow-up testing per NIJ sampling plans

Field data from warranty claims or incident reports

For large manufacturers, integrate with CRM and ERP systems to automate defect tracking and performance analysis.

7. Audit, Review, and Continuous Improvement

Regular self-assessments enhance system maturity and maintain compliance readiness.

Recommendations:

Quarterly audits of traceability logs

Spot checks on random reports for consistency

Review templates for NIJ 0101.07 or ASTM standard updates

Document corrective and preventive actions (CAPAs)

Annual staff retraining strengthens adoption and data accuracy across R&D and quality teams.

Leveraging Digital Infrastructure for Superior Control

Adopting the right digital infrastructure—from Document Management Systems (DMS) to Product Lifecycle Management (PLM) tools—can transform how armor developers handle compliance, traceability, and collaboration.

While DMS platforms focus on secure document control, versioning, and audit trails, PLM systems manage the entire product lifecycle—from design and material selection through testing, certification, and production. Together, they create a unified digital backbone that supports both ISO/BA 9000 quality systems and NIJ compliance frameworks.

Benefits Include

Real-time access, versioning, and traceability across teams

Automated audits and compliance reporting

Integration with test labs, ERP, or CAD tools

Secure logs, encryption, and multi-factor authentication

Centralized storage for NIJ/ITAR-related data and controlled documents

Recommended DMS & PLM Tools for Small to Mid-Size Companies

1. Hyland Alfresco (Community Edition – Open Source DMS)

Type: Document Management System (Open Source)

Why it works:

Enterprise-grade, open-source platform that supports version control, audit logs, metadata tagging, and user-based permissions.

Easily integrates with Microsoft Office, Google Workspace, and existing quality systems.

Best for: Teams needing a scalable DMS without high licensing costs.

Cost: Free (open-source); paid cloud option available.

Website: https://www.hyland.com/en/solutions/products/alfresco-platform

2. Arena PLM (by PTC)

Type: Product Lifecycle Management (Cloud-Based SaaS)

Why it works:

Designed for manufacturers in regulated industries, Arena PLM connects product design, quality, and compliance data in one centralized, cloud-native platform.

It integrates seamlessly with CAD systems and quality management modules, making it ideal for armor manufacturers operating under NIJ, ISO 9001:2015, and BA 9000 standards.

Best for: Teams needing integrated PLM and QMS capabilities to manage product design, documentation, and certification records.

Cost: Subscription-based SaaS (quote by request).

Website: arenasolutions.com/platform/plm/

3. Odoo PLM / Document Module

Type: Hybrid ERP + PLM + DMS (Open Source Core)

Why it works:

Combines document management, product lifecycle tracking, and workflow automation.

Integrates directly with manufacturing, quality, and inventory modules.

Best for: Companies wanting one modular system that scales into ERP.

Cost: Free community edition; paid modules start ~$25/user/month.

Website: https://www.odoo.com/

4. Zoho WorkDrive (Affordable Cloud DMS)

Type: SaaS Document Management System

Why it works:

Intuitive cloud file management with strong access controls and audit trails.

Real-time collaboration and file sharing for remote QA, design, or compliance teams.

Best for: Teams needing quick deployment and secure file sharing without on-prem hosting.

Cost: ~$2–$4/user/month.

Website: https://www.zoho.com/workdrive/

5. DocuWare Cloud

Type: Document Management System (SaaS)

Why it works:

ISO-compliant document control, versioning, and workflow automation.

Great balance between security and usability, with built-in e-signature features.

Best for: Small to mid-size manufacturers needing structured approvals and audit trails.

Cost: Starts around $300/month for small teams.

Website: https://start.docuware.com/

For Future Scalability

Once teams outgrow small systems, consider Arena PLM (by PTC) or Autodesk Fusion 360 Manage for full digital thread integration—both integrate with NIJ test data, CAD files, and QMS modules, supporting BA 9000 or ISO 9001:2015 frameworks.

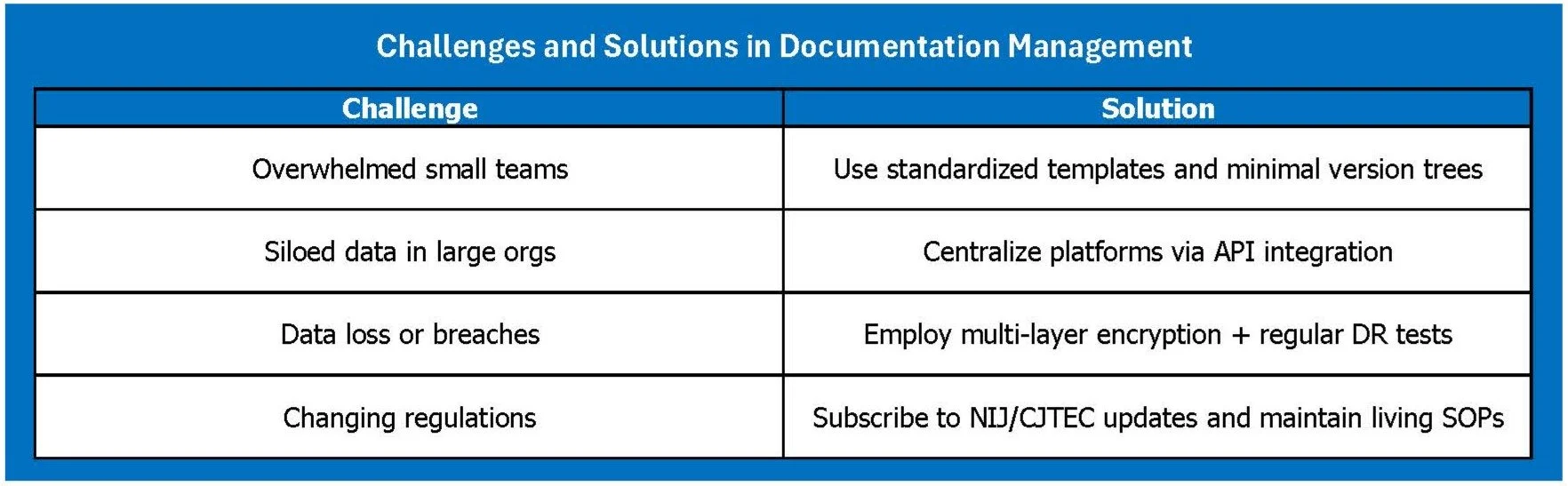

Document Challenges and Solutions Table

How IntelAlytic Supports Documentation and Data Systems for Armor Manufacturers

IntelAlytic partners with body-armor and defense manufacturers to design, implement, and manage documentation and data-tracking frameworks aligned with industry standards.

Our services include:

Quality-management-system development based on BA 9000 and ISO 9001:2015 frameworks.

Data-infrastructure mapping to ensure seamless traceability across R&D and production.

Audit preparation and compliance support for NIJ testing, defense procurement, and BA 9000 readiness.

Process-automation consulting to digitize documentation control, minimize manual tracking, and safeguard data integrity.

From prototype to production, IntelAlytic helps manufacturers transform documentation into an operational advantage — ensuring that every test, certification, and material trace is organized, verifiable, and audit-ready.

Because in ballistic protection, data integrity is product integrity.

Need help building your documentation and data-tracking systems?

IntelAlytic provides direct consulting and implementation support for armor manufacturers and defense contractors.

Email: support@intelalytic.com

Learn more: www.intelalytic.com

Let’s build the systems that keep your data — and your protection — verifiable, traceable, and compliant.