The Evolution of Body Armor Design: Beyond the Triangle to a Pentagon of Priorities

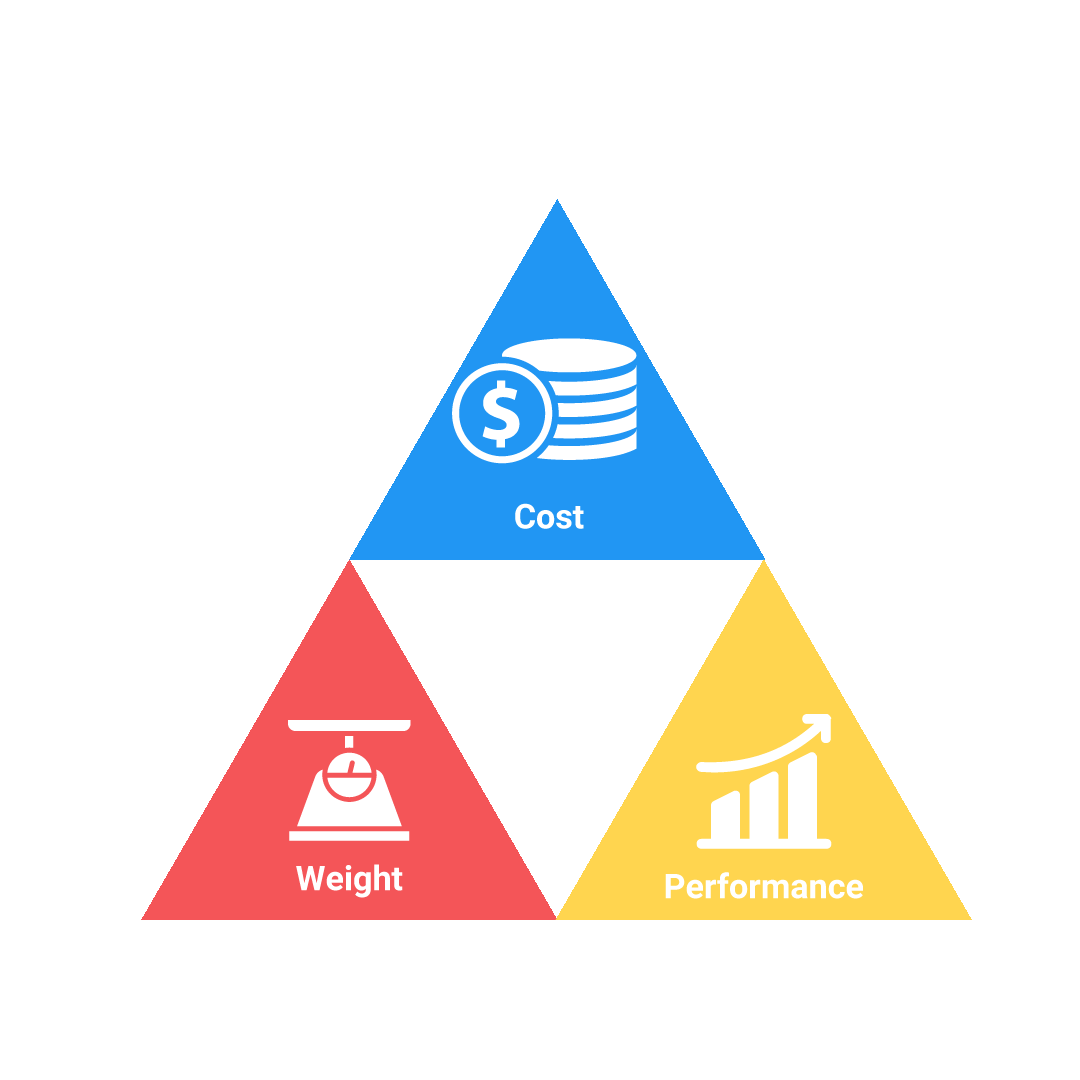

For decades, the design and development of body armor have been dominated by a seemingly straightforward trade-off among three critical factors: weight, cost, and performance. This traditional view, often visualized as a triangle, has guided manufacturers in making decisions that balance these competing demands. However, the reality of body armor design is far more complex. Today, experts and manufacturers recognize that a successful protective platform is better represented by a pentagon that includes two additional, equally crucial factors: thickness and comfort. This article explores the five keys to a successful protective platform, revealing why it's time to move beyond the triangle to embrace a more nuanced and comprehensive approach.

Weight: The Pivotal Balance in Body Armor Design

Introduction to Weight Considerations

In body armor design, weight is not just a specification—it's a critical factor defining protective gear's usability and efficiency. The evolution of body armor reflects a continuous quest to enhance protection while minimizing weight, ensuring that the armor supports rather than encumbers the wearer.

Soft Armor Innovations

Soft body armor is the first defense against handgun threats and shrapnel. The latest advancements have introduced vests weighing as low as 0.70 psf, using materials like UHMWPE and advanced aramids. These materials have revolutionized soft armor by offering an unparalleled strength-to-weight ratio, significantly reducing wearer fatigue without compromising protection.

The Spectrum of Soft Armor Weight

Soft armor showcases a spectrum of weights, with heavier options providing enhanced protection at the expense of increased weight. This variation necessitates a careful balance, especially in roles requiring stealth or prolonged wear, where weight and thickness are critical for operational effectiveness.

Hard Armor: A Study in Weight vs. Protection

The weight consideration intensifies by moving to hard armor to counter rifle threats. The distinction between Level IV and Level III plates exemplifies the trade-off between protection and weight:

Level IV Plates: Engineered to defeat armor-piercing rounds, these plates are heavier, typically weighing between 7 and 8 pounds each. Their weight reflects their robust protective capability.

Level III Plates: Lighter, weighing between 3 and 5 pounds, are tailored to stop standard rifle bullets, offering a balance between protection and mobility conducive to a broader application range.

Innovative Solutions: Special Threat and ICW Plates

The body armor industry innovates with "special threat" plates and ICW (In Conjunction With) configurations. These innovations allow for customized protection against specific threats and lighter, thinner plates when used with soft armor, pushing the boundaries of weight reduction.

The Modern Armor Challenge

Envisioning the body armor design challenge as equipping a modern-day knight, it's clear that today's protective gear combines historical principles with cutting-edge science. The focus on weight optimization does not merely cater to comfort but is imperative for tactical agility and endurance in the field.

The Ongoing Quest for Balance

The critical role of weight in body armor design underscores the industry's commitment to advancing protective technologies. As materials science progresses, the future of body armor lies in achieving even more significant reductions in weight without compromising on protective capabilities. The journey towards the ideal balance of weight, protection, cost, comfort, and performance is a testament to the relentless pursuit of innovation, ensuring the safety and operational effectiveness of those in harm's way.

Thickness: Redefining Body Armor for the Modern Era

The Significance of Thickness in Body Armor

Thickness in body armor is a critical determinant of both protection and wearability. It directly influences the gear's comfort, mobility, and overall effectiveness. As protective technology evolves, focusing on reducing the thickness without compromising protection has become paramount, leading to significant innovations in material science and design.

Advancements in Material Science

The revolution in body armor thickness can be attributed mainly to developing advanced materials such as Ultra-High-Molecular-Weight Polyethylene (UHMWPE) and ceramic composites. These materials have enabled manufacturers to produce armor that combines robust protection with significantly reduced bulk. For instance, modern soft armor can now offer NIJ Level IIIA protection in layers that are often less than half an inch thick, a testament to the strides made in material engineering.

Optimizing Hard Armor

Hard armor has also transformed, with current manufacturing techniques allowing for Level IV plates less than an inch thick. This reduction in thickness and the subsequent decrease in weight significantly enhance the user's mobility and endurance, crucial factors in high-risk environments.

Balancing Act: Thickness versus Other Factors

Weight: The reduction in thickness naturally contributes to a decrease in weight, enhancing operational agility and reducing wearer fatigue over extended periods.

Performance: Thinner armor must still meet stringent performance standards. This challenge is met through innovative designs and the strategic layering of composite materials, ensuring the armor withstands various threat levels.

Cost: The investment in advanced materials and technologies to reduce thickness and maintain performance often increases the cost. However, the value provided by enhanced wearability and protection justifies this investment.

Comfort: Reduced thickness significantly improves comfort, making armor less intrusive and more conducive to being worn correctly and consistently, even in covert situations.

The Future of Thin Armor

Envisioning the future of body armor, one can imagine protection so thin and flexible it resembles everyday clothing yet capable of stopping advanced ballistic threats. This vision drives the industry forward, blending cutting-edge science with the practical needs of users to create armor that offers the ultimate balance of protection, comfort, and mobility.

The Evolution Continues

Pursuing thinner body armor represents a critical evolution in protective gear design. By pushing the boundaries of material science and engineering, the industry aims to provide modern protectors with armor that is not just a tool for survival but an enhancement to their operational capabilities. As we look to the future, the potential for even thinner, more effective body armor holds the promise of transforming the landscape of personal protection, ensuring those on the front lines have the best possible defense in an ever-changing world of threats.

Performance: The Heartbeat of Body Armor Innovation

Defining Performance in Protective Gear

Performance is the linchpin of body armor design, embodying the gear's effectiveness against threats like bullets, shrapnel, and edged weapons. This critical aspect goes beyond mere compliance with standards; it is about delivering real-world survivability in the most demanding situations. The National Institute of Justice (NIJ) provides benchmarks for armor performance, but leading-edge manufacturers aim far beyond these criteria, driven by the imperative to save lives.

Material and Design Innovations

Significant material and engineering breakthroughs mark the evolution of body armor performance. Integrating aramid fibers and Ultra-High-Molecular-Weight Polyethylene (UHMWPE) in soft armor has dramatically enhanced protection against ballistic threats and fragmentation. Concurrently, hard armor developments have incorporated composite ceramics and advanced polyethylene, enabling lighter, more potent protection against rifle threats.

Balancing the Performance Equation

Weight vs. Performance: The hypothesis that increased protection results in increased weight is challenged by innovative material use and intelligent design. The goal is to elevate protection while minimizing weight to preserve mobility and reduce wearer fatigue.

Thickness vs. Performance: Advances in materials technology have enabled the production of thinner armor that does not compromise protection. This progress addresses the wearer's need for comfort and discretion, particularly in covert operations.

Cost vs. Performance: High-performance materials and cutting-edge technologies command a premium. However, the investment in advanced armor is justified by the critical need for adequate protection in high-risk scenarios.

Comfort vs. Performance: Ergonomic design and the strategic distribution of armor weight are essential to ensure that high-performance gear remains wearable for extended periods. Ventilation and flexibility are also crucial to maintaining wearer comfort without compromising protection.

Real-World Impact and Innovation

In the crucible of law enforcement and military operations, where threats are unpredictable and varied, the performance of body armor is non-negotiable. The blend of soft and hard armor elements tailored to specific threat profiles exemplifies the industry's response to these challenges. Continuous innovation in materials and design is essential to ensure that body armor keeps pace with evolving threats, providing wearers with the confidence to confront danger head-on.

The Future of Armor Performance

As we project into the future, envisioning an "Armor Olympics" symbolizes the competitive spirit driving manufacturers to excel in armor performance. This relentless pursuit of excellence is not just about technical achievement; it's about pushing the boundaries of what's possible to ensure the highest level of protection for those in harm's way.

The Commitment to Excellence

The ongoing advancements in body armor performance underscore a profound commitment to safeguarding lives through innovation. As threats evolve and operational requirements transform, the industry's dedication to enhancing performance while balancing weight, thickness, cost, and comfort ensures that first responders and military personnel are equipped with the best possible protection. This enduring focus on performance innovation is the cornerstone of modern body armor design, embodying the collective effort to protect those who face danger in the service of others.

Cost: The Economic Dimension of Body Armor Development

Overview of Cost in Body Armor Production

The economic aspect of body armor encompasses more than just the final price tag; it involves a complex interplay of manufacturing costs, material expenses, innovation investments, and market dynamics. Achieving cost-effectiveness while maintaining or enhancing the level of protection is a pivotal challenge manufacturers face. This balancing act ensures life-saving gear is accessible to those who need it most, from frontline law enforcement to civilians in high-risk situations.

Material Costs and Innovation

The drive for advanced body armor has escalated the demand for materials like Ultra-High-Molecular-Weight Polyethylene (UHMWPE), aramids, and ceramic composites. These materials, chosen for their superior protective qualities and lightweight properties, inherently come with higher production costs. The development phase, which includes rigorous testing and certification to meet safety standards, further adds to the financial investment required to bring new armor solutions to market.

Efficiency and Economies of Scale

Manufacturing efficiency and economies of scale play crucial roles in managing the cost of body armor. As manufacturers refine production techniques and increase output, the per-unit cost of armor decreases, a saving that can be passed on to purchasers. Additionally, technological advancements in manufacturing processes contribute to reducing waste and enhancing product quality, further influencing cost efficiency.

The Cost-Performance Nexus

The relationship between cost and performance is nuanced. High-performance body armor, equipped to withstand emerging threats, necessitates investment in cutting-edge materials and design innovation. Manufacturers must navigate this relationship carefully, ensuring that enhancements in protection do not render the armor prohibitively expensive for its intended users.

Enhancing Accessibility Through Funding

Accessibility to body armor is significantly influenced by funding and grant programs, especially for budget-constrained organizations like small law enforcement agencies. These programs, often supported by governmental initiatives, play a vital role in ensuring that economic barriers do not compromise the safety of those on the front lines.

Case Study: Balancing Act in Action

Consider a scenario where a municipal police department seeks to upgrade its body armor amidst budget constraints. Manufacturers offering a spectrum of options, from essential protection to advanced multi-threat armor, allow the department to make cost-effective decisions without compromising officer safety. This approach exemplifies the industry's commitment to providing scalable solutions that cater to diverse financial capabilities and protection needs.

The Body Armor Bazaar: A Conceptual Marketplace

I envision a marketplace where body armor's cost, comfort, and protection converge, highlighting the industry's dynamic nature. This "Body Armor Bazaar" metaphorically represents the diverse offerings available to consumers, emphasizing the importance of informed decision-making in selecting gear that balances cost with critical protective capabilities.

Conclusion: Navigating the Cost Component

The economic considerations in body armor design and production are integral to equipping individuals with the necessary protection. By innovating in materials science, optimizing manufacturing processes, and leveraging funding opportunities, the body armor industry strives to make protective gear effective and accessible. This ongoing effort ensures that cost does not become a safety barrier, embodying the industry's overarching commitment to safeguarding lives.

Comfort: A Paradigm Shift in Body Armor Design

The Evolution of Comfort in Protective Gear

Historically, body armor design has prioritized protection, often at the expense of wearer comfort. However, the understanding has deepened that comfort is not merely about the absence of discomfort but a critical feature that enhances the operational effectiveness of protective gear. Modern body armor design integrates comfort as a fundamental aspect, recognizing its impact on the wearer's ability to perform duties effectively and safely over extended periods.

Innovations Enhancing Comfort

Pursuing comfort in body armor has led to significant advancements in ergonomic design, material selection, and construction techniques. Manufacturers have focused on developing armor that conforms to the body's shape, reducing bulk and improving fit. Innovations in materials have introduced lighter, more breathable fabrics that facilitate temperature regulation and moisture management, essential for maintaining comfort during prolonged use.

Ventilation and Heat Management

Addressing the overheating challenge, contemporary body armor incorporates advanced ventilation systems to promote air circulation. This feature is crucial in maintaining a comfortable microclimate between the armor and the wearer, especially in hot climates or during intense physical activity.

Flexibility and Load Distribution

Enhanced flexibility and strategic weight distribution are at the forefront of ergonomic improvements in body armor. These advancements allow for a full range of motion, which is critical in dynamic environments where rapid response is essential. By evenly distributing the armor's weight, manufacturers minimize the strain on any single part of the body, reducing the risk of fatigue and injury.

The Direct Link Between Comfort and Compliance

The level of comfort provided by body armor directly influences wearer compliance. Comfortable armor is more likely to be worn correctly and consistently, ensuring its protective benefits are fully realized. Recognizing this, manufacturers prioritize comfort to improve the likelihood of adherence to wearing protocols, ultimately enhancing the gear's effectiveness.

Real-World Implications

The practical impact of comfort-focused design is evident in the daily experiences of law enforcement officers and military personnel. Armor that balances protection with comfort supports these individuals in their relentless pursuit of safety and justice, allowing them to concentrate on their missions without being burdened by their gear.

Forward-Looking: The Future of Comfort in Armor Design

As the body armor industry progresses, the emphasis on comfort continues to drive innovation, leading to protective gear that resembles a natural extension of the wearer. This evolution signifies a paradigm shift, where comfort and protection are not mutually exclusive but integrated to enhance body armor's overall effectiveness.

Comfort as a Cornerstone of Modern Armor

The advancement of comfort in body armor underscores a holistic approach to design, where the wearer's needs are central. This approach enhances the protective capabilities of body armor and ensures that those who face danger in the line of duty can do so with enhanced confidence and endurance. As we look to the future, the integration of comfort into body armor design promises to redefine the standards of protective gear, ensuring it is not only practical but also a faithful ally to those it is designed to protect.

Beyond the Triangle: A Pentagonal Reality

Moving from viewing body armor design as a balance among three factors to a more comprehensive pentagonal model reflects a deeper understanding of the complexities of creating adequate ballistic-resistant platforms. It acknowledges that while weight, cost, and performance are foundational considerations, they are not the only ones. Thickness and comfort play equally vital roles in the success of a protective platform, influencing everything from operational effectiveness to wearer compliance.

The future of body armor design lies in the ability of manufacturers to innovate within this pentagonal framework, finding new materials, designs, and manufacturing techniques that address all five key factors. As technology advances, so will the possibilities for creating body armor that provides unparalleled protection without compromise.

We recognize that the development of body armor is a testament to the importance of evolving our understanding of protective gear. By embracing the pentagonal model of design priorities, manufacturers can create products that meet the complex and varied needs of modern users, ensuring that those who put themselves in harm's way have the best possible protection.

Elevate Your Position in the Armor Market with IntelAlytic

In the competitive arena of body armor design, standing out requires more than just innovation—it demands a strategic partnership that understands the intricacies of the market and the technical challenges of product development. IntelAlytic is your ideal ally in this endeavor. Our team of experts specializes in leveraging cutting-edge advancements in materials science and manufacturing processes and deep market insights to tailor solutions that address your specific needs.

If you aim to redefine protection standards, enhance the wearability of your products, or strike the perfect balance among weight, cost, performance, thickness, and comfort, look no further. IntelAlytic is committed to transforming your challenges into victories, ensuring your offerings meet the demands of modern users, and leading the market in quality and innovation.

Partner with IntelAlytic and take the first step towards industry dominance. Let our expertise catalyze your success, guiding you through the complexities of product development and market positioning to secure your place at the forefront of the armor industry.

Learn More About IntelAlytic

Explore IntelAlytic Services

Follow us on LinkedIn for daily tips and resources