NIJ vs. VPAM: Comparing the World’s Leading Ballistic Protection Standards

When lives hinge on armor performance, precision about standards is not optional. In ballistic protection, two frameworks dominate the global conversation: the NIJ standards (U.S.) and the VPAM guidelines (Europe/NATO).

This guide explains how NIJ 0123.00 (levels & threats) and NIJ 0101.07 (performance & test methods) work together for U.S. body armor and how they compare to the VPAM APR, VPAM HVN 2009, VPAM BSW 2006, and VPAM BRV guidelines used across Europe.

If you specify, buy, or certify ballistic protection, this is your roadmap.

How NIJ 0123.00 and NIJ 0101.07 Work Together

The National Institute of Justice (NIJ) governs the U.S. body armor standard through the Criminal Justice Technology Testing and Evaluation Center (CJTTEC) as detailed in the Compliance Testing Program (CTP). Two linked documents define today’s system:

NIJ 0123.00 (2023): Specifies the ballistic protection levels and test threats.

Handgun levels: HG1, HG2

Rifle levels: RF1, RF2, RF3

NIJ 0101.07 (2023): Sets the test methods and pass/fail criteria for torso body armor.

Requires perforation + backface deformation (BFD) assessment on calibrated Roma Plastilina clay.

Limits BFD to 44 mm for soft armor.

Expands shot placements (edge, obliquity, and crown shots).

Imposes strict pre-conditioning (heat, humidity, mechanical flex).

Representative NIJ Threats (per NIJ 0123.00)

HG1:

9×19 mm FMJ RN at 398 m/s

357 Magnum JSP at 436 m/s

HG2:

9×19 mm FMJ RN at 448 m/s

.44 Magnum JHP at 436 m/s

RF1:

7.62×51 mm M80 Ball at 847 m/s

7.62×39 mm MSC at 732 m/s

5.56×45 mm M193 at 990 m/s

RF2:

Includes all RF1 threats, plus;

5.56×45 mm M855 at 950 m/s

RF3:

.30-06 M2 AP at 878 m/s

Use case: NIJ standards are mandatory for U.S. law enforcement procurement and serve as the global reference point for torso body armor.

Method highlights (0101.07):

Perforation + Backface Deformation (P-BFD) on calibrated clay; 44 mm BFD threshold for soft armor.

Expanded shot placements (edge/obliquity and crown shots on curved plates).

Strict pre-conditioning (heat, humidity, mechanical/mechanical flex) before live-fire.

Transition: agencies can continue using legacy 0101.06 CPL active models during the 0101.07 roll-out; NIJ is publishing addenda with clarifications to both 0101.07 and 0123.00.

The European Framework: VPAM

The Vereinigung der Prüfstellen für Angriffshemmende Materialien und Konstruktionen (VPAM) is an association of approved test labs in Europe. VPAM does not operate a single “body armor standard.” Instead, it publishes multiple guidelines, each focused on different equipment types.

Correct VPAM Guidelines

VPAM APR (Allgemeine Prüfrichtlinien)

General ballistic test guideline for materials.

Defines APR levels 1–10. Levels 1–5 cover handgun, higher levels 6-10 cover rifle/AP threats.

Very heavy anti-materiel threats are specified via VPAM AND-SoM (special tests).

Pass/fail = penetration/no penetration using a 0.5 mm aluminum witness plate is set 150 ± 5 mm behind the target (no clay BFD).

VPAM HVN 2009 (Helmets, Visors, Neck protection)

Applies specifically to helmets and visors.

VPAM HVN 2009 includes BFD criteria and head-specific injury limits, which are stricter than NIJ torso BFD criteria and use helmet-appropriate backing per VPAM HVN 2009.

VPAM BSW 2006 (Bullet-resistant Vests)

Applies to soft body armor vests.

Uses APR threats but with vest-specific placement and conditions.

VPAM BRV (Bullet-Resistant Vehicles)

Applies to complete vehicles, VR1–VR10.

Evaluates seams, glazing, and structural weak points under multi-hit and obliquity.

VPAM AND-SoM (Additional Special Tests)

Covers heavy threats not in APR (e.g., .50 BMG, 14.5×114 mm).

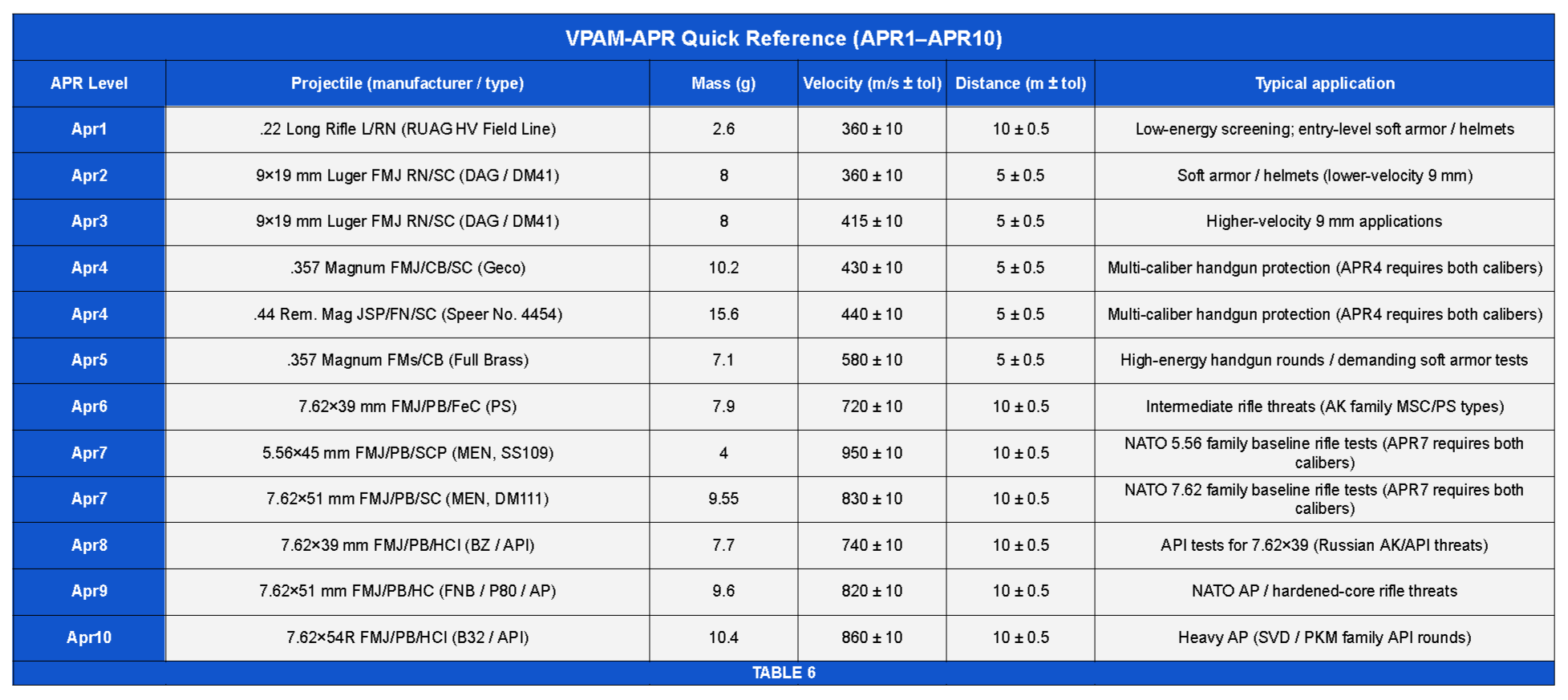

Representative VPAM-APR test threats (per VPAM-APR, Edition 3)

APR1: .22 Long Rifle, L/RN, 2.6 g — RUAG HV Field Line — 360 ± 10 m/s, 10 ± 0.5 m

APR2: 9×19 mm Luger, FMJ/RN/SC, 8.0 g — DAG / DM41 — 360 ± 10 m/s, 5 ± 0.5 m

APR3: 9×19 mm Luger, FMJ/RN/SC, 8.0 g — DAG / DM41 — 415 ± 10 m/s, 5 ± 0.5 m

APR4: (both calibers required at this level)

.357 Magnum, FMJ/CB/SC, 10.2 g — Geco — 430 ± 10 m/s, 5 ± 0.5 m

.44 Remington Magnum, JSP/FN/SC, 15.6 g — Speer No. 4454 — 440 ± 10 m/s, 5 ± 0.5 m

APR5: .357 Magnum, FMs/CB (full brass), 7.1 g — Specification IAW VPAM — 580 ± 10 m/s, 5 ± 0.5 m

APR6: 7.62×39 mm, FMJ/PB/FeC, 7.9 g — PS — 720 ± 10 m/s, 10 ± 0.5 m

APR7: (both calibers required at this level)

5.56×45 mm (SS109 / .223 Rem), FMJ/PB/SCP, 4.0 g — MEN, SS109 — 950 ± 10 m/s, 10 ± 0.5 m

7.62×51 mm (DM111 / .308 Win), FMJ/PB/SC, 9.55 g — MEN, DM111 — 830 ± 10 m/s, 10 ± 0.5 m

APR8: 7.62×39 mm, FMJ/PB/HCI (BZ / API), 7.7 g — BZ — 740 ± 10 m/s, 10 ± 0.5 m

APR9: 7.62×51 mm (.308 Win), FMJ/PB/HC (P80 / AP), 9.6 g — FNB / P80 — 820 ± 10 m/s, 10 ± 0.5 m

APR10: 7.62×54 R, FMJ/PB/HCI (B32 / API-I), 10.4 g — B32 — 860 ± 10 m/s, 10 ± 0.5 m

Special/Heavy tests (VPAM AND-SoM — not part of APR1–10; used for special / anti-materiel ammunition types):

Example: 12.7×99 mm (.50 BMG) — M2 AP / API / SLAP variants — representative velocities and distances are specified in AND-SoM (see VPAM follow-on docs).

Example: 14.5×114 mm — B32 API and related variants — likewise defined in AND-SoM for special tests. VPAM

Notes: See AND-SoM for exact projectile & velocity

Bottom line:

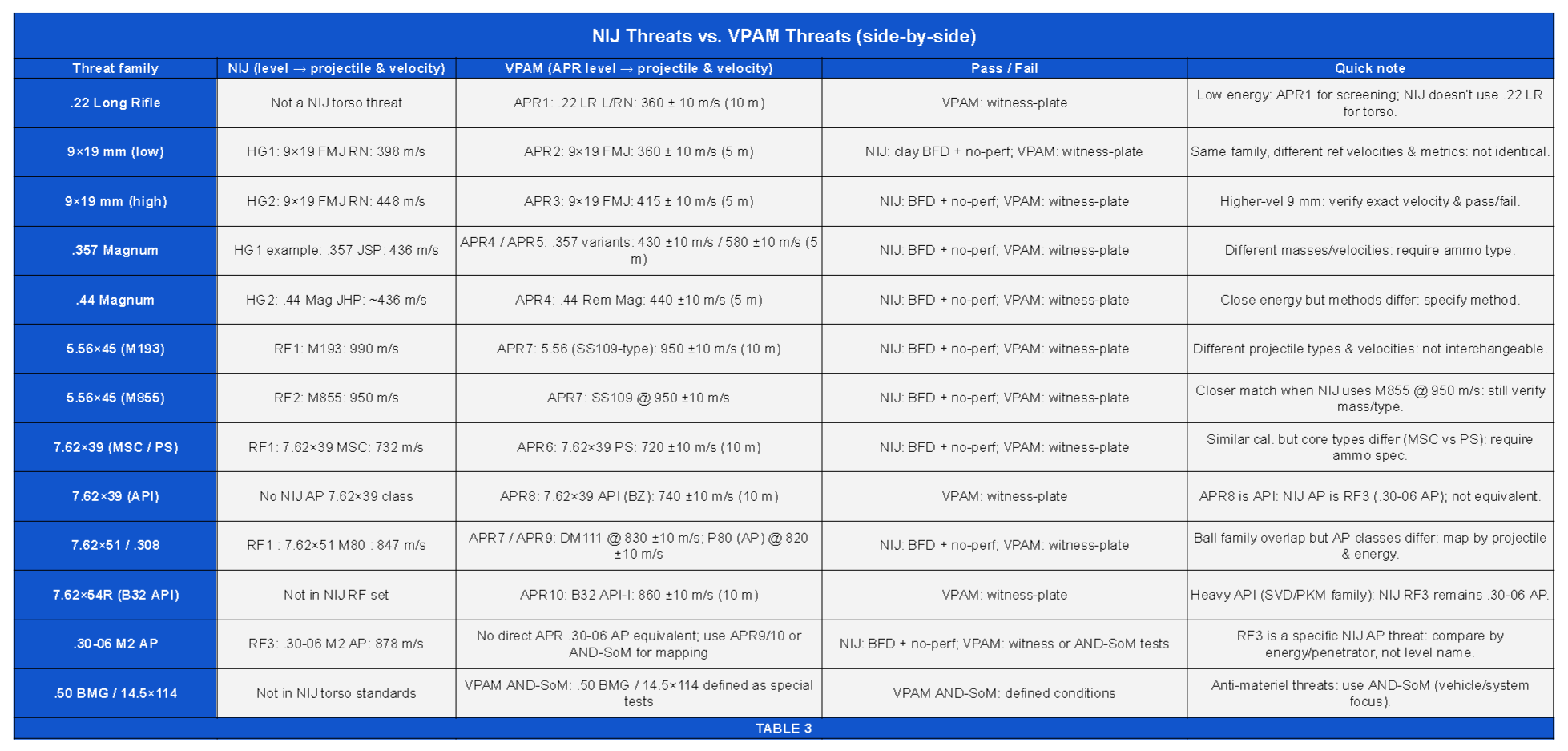

NIJ vs. VPAM: Detailed Comparison

NIJ vs. VPAM: What Maps — and What Doesn’t

There is no official one-to-one crosswalk between NIJ and VPAM. The standards differ in scope, test philosophy, shot placement, conditioning, ammunition definitions, and pass/fail metrics. Anyone who promises a simple level equivalence is oversimplifying a technical mismatch that can have real safety and procurement consequences.

Guiding rule

Compare by projectile + velocity + method — not by level name. If two certifications use the same projectile at the same reference velocity and the same pass/fail criterion, then they are comparable. Otherwise, they are not.

Practical examples (illustrative, not equivalent)

NIJ RF3 evaluates a .30-06 M2 AP threat (per NIJ 0123.00 / 0101.07).

VPAM APR levels are defined by projectile and velocity (e.g., APR8 = 7.62×39 API at ~740 m/s; APR9 = 7.62×51 P80 AP at ~820 m/s).

These are different projectiles and velocities — RF3 is an AP .30-06; APR8/9 are 7.62 family API/AP threats. They are not equivalent. Always cross-check the exact projectile, mass, and velocity.

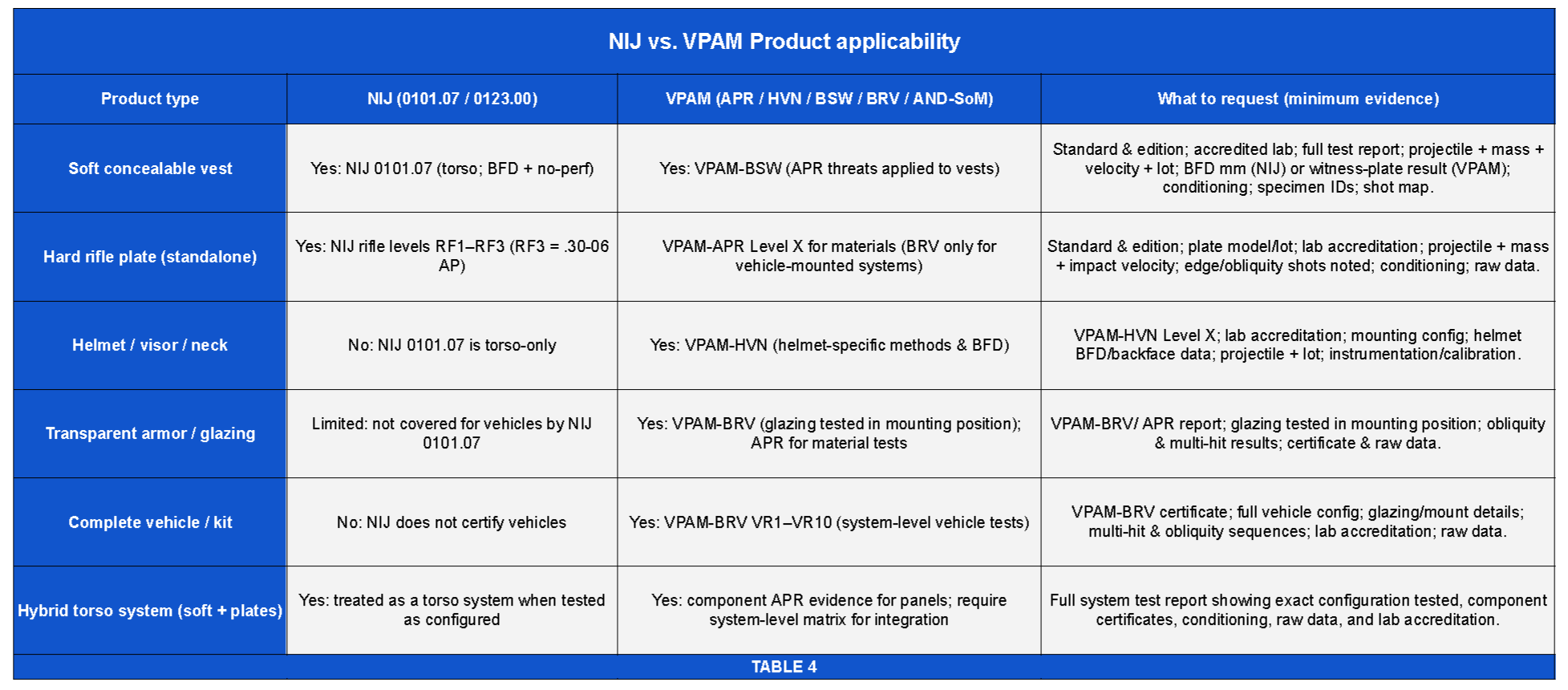

Scope differences (short)

NIJ 0101.07 / 0123.00 — Torso body armor (soft armor + plates). Pass/fail = perforation and Back-Face Deformation (BFD) on clay (44 mm limit for soft armor). Mandatory pre-conditioning is required.

VPAM APR / VPAM HVN 2009 / VPAM BSW 2006 / BRV — APR covers material levels (APR Levels defined by projectile/velocity), HVN for helmets/visors (includes helmet-specific BFD criteria), BSW for vests (vest placements/conditions), BRV for whole vehicles (system-level, glazing, seams, obliquity, multi-hit). VPAM primarily uses a penetration (witness plate) pass/fail approach in APR; helmet HVN uses BFD criteria appropriate for head protection.

Why level names deceive

Industry shorthand like “PM3” or “PM8” is legacy terminology. Use “VPAM-APR Level X”, “VPAM-HVN Level X”, “VPAM-BSW Level X”, or “VPAM-BRV VRX” in specifications. If you see “PM#” in vendor literature, treat it as legacy shorthand and require the vendor to cite the precise VPAM guideline and edition.

Recommended procurement/spec language

Use these templates to ensure unambiguous requirements and enforceable test evidence.

NIJ (torso armor)

“Armor shall be certified (Compliant) to NIJ Standard 0101.07 (including all applicable addenda) and listed as “ACTIVE” on the NIJ CPL at protection level(s) per NIJ Standard 0123.00: HG1 / HG2 / RF1 / RF2 / RF3 as specified. Supplier must provide the full NIJ CTP test report from an NIJ-approved laboratory showing: ammunition manufacturer/type and lot, conditioning regimen, clay BFD results (mm), shot placements and specimen IDs, test date, and laboratory approval number. Failure to provide the complete test report voids acceptance.”

VPAM APR (material / panel)

“Panel shall meet VPAM-APR Level X (Edition 3) tested per VPAM-APR (Edition 3). Provide a VPAM-approved laboratory test report showing: exact projectile designation, projectile mass, ammunition manufacturer/type and lot, firing distance, impact velocity (m/s ± tolerance), witness-plate no-penetration result, witness-plate spacing (150 ± 5 mm), conditioning (if applied), angle of attack (AOA) used, and certificate number. For heavy or non-APR threats, specify AND-SoM testing and include the AND-SoM reference.”

VPAM HVN 2009 (helmets/visors)

“Helmet shall be certified to VPAM-HVN Level X per VPAM HVN 2009. Provide VPAM HVN 2009 test report showing BFD/backface displacement criteria used, helmet mounting configuration, instrumentation, and lab approval.”

VPAM BRV (vehicles/systems)

“Vehicle shall be certified to VPAM-BRV VRX per VPAM-BRV. Test report must document the vehicle configuration, glazing tested in mounting position (if applicable), obliquity angles, multi-hit sequences, witness-plate / glazing results, and full laboratory test data and certificate.”

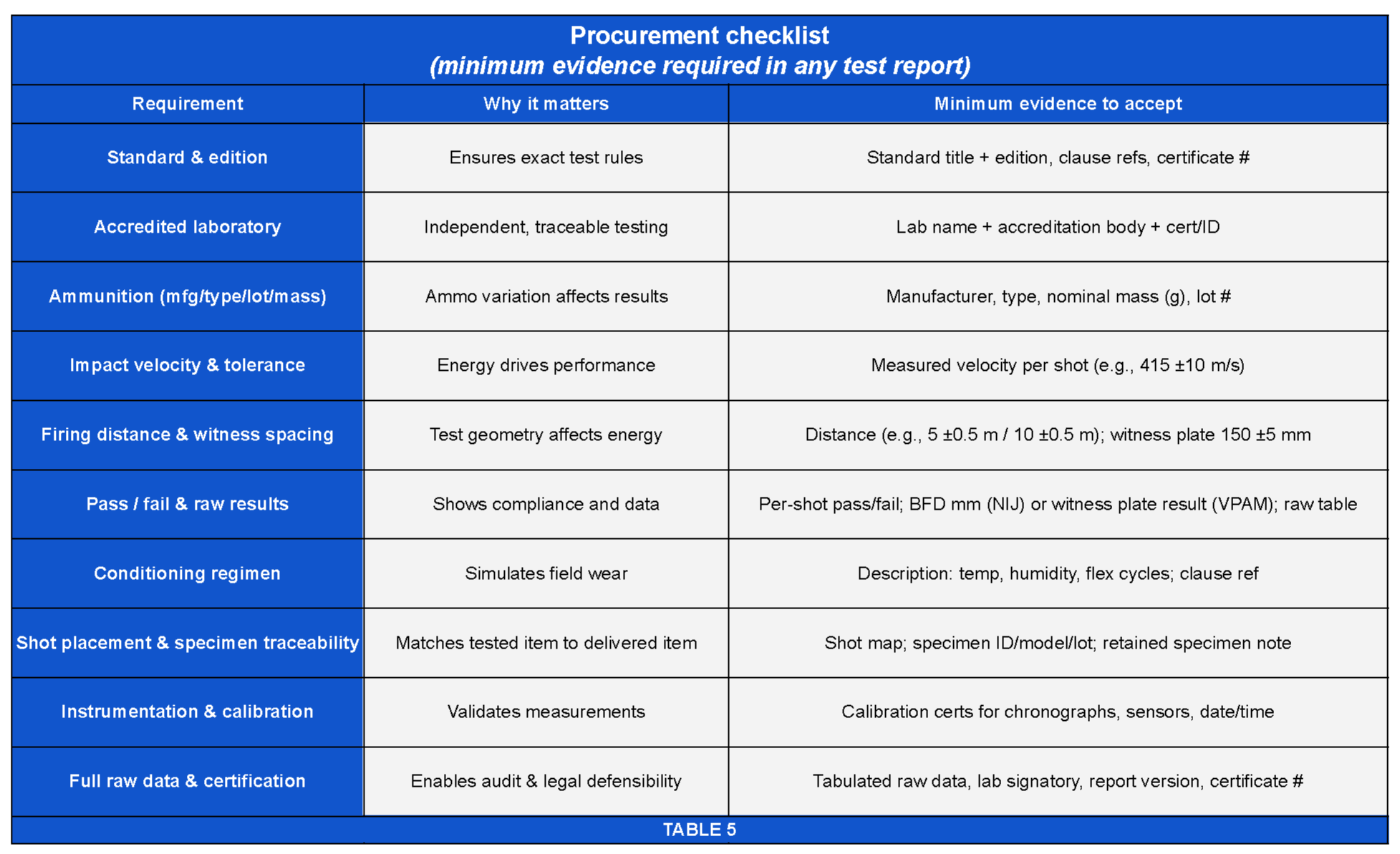

General QA / evidence clause (add to any spec)

“All reports must be issued by a VPAM-approved or NIJ-approved test laboratory, include raw data, ammunition lot numbers, instrumentation calibration records, test specimen traceability, and the edition/version of the standard used. Supplier shall retain and make available retained specimens for cross-inspection for 90 days post-report.”

Quick procurement checklist

Standard and edition explicitly referenced (e.g., VPAM-APR Edition 3; NIJ 0101.07).

Approved lab name and certificate number included.

Full test report with raw data, ammunition lot, and specimen IDs.

Pass/fail metric spelled out (BFD mm or witness-plate penetration).

Conditioning regimen documented.

Witness plate spacing (VPAM) / clay type (NIJ) documented.

Ammunition manufacturer/type as per the standard table.

If a special threat is required, reference AND-SoM (VPAM) or a defined custom test matrix.

Final note for engineers and scientists

If you need to translate requirements between NIJ and VPAM for a single procurement, build a test matrix that lists each required projectile, its required reference velocity (m/s), the pass/fail criterion (penetration/no-penetration OR BFD limit), and conditioning/angle. Then, require the vendor to provide a matching test report. That removes level-name ambiguity and keeps the contract enforceable.

NIJ vs. VPAM: Origin and Comparison

Related frameworks (for context)

UK — Home Office Body Armour Standard (2017) — Published by the Home Office (CAST/HOSDB program), the 2017 Body Armour Standard defines minimum performance requirements and test methods for ballistic, knife, and spike protection for UK law-enforcement body armour, plus guidance on fit, coverage, and in-service management.

Germany — Technische Richtlinien (TR) — German technical directives (TR) issued by police technical institutes (e.g., PTI / Polizei-Technisches Institut) and related agencies define requirements for ballistic helmets, protective vests, and body-protection systems, combining ballistic, stab/spike, and human-factors criteria used in German federal/state procurement.

These are region-specific standards but are frequently referenced in cross-border procurements and technical evaluations where UK/German acceptance or interoperability is required. When writing specs, always cite the standard title and edition (e.g., “Home Office Body Armour Standard 2017, Publication 012/17” or the TR document title and revision date).

NIJ Threats vs. VPAM Threats (side-by-side)

NIJ vs. VPAM Product applicability

NIJ vs VPAM Procurement checklist

VPAM-APR Quick Reference (APR1–APR10)

Which path fits your mission?

Choose NIJ 0101.07 + 0123.00 when you:

Supply U.S. law enforcement or must meet NIJ CTP procurement requirements.

Need clay-based perforation + backface deformation (P-BFD) limits, standardized pre-conditioning, and the HG / RF nomenclature (including AP at RF3).

Choose VPAM-APR / VPAM-BRV when you:

Serve EU/NATO markets or manage vehicle / transparent-armor programs.

Need penetration-centric results, multi-hit and obliquity testing, and system-level weak-point evaluation (glazing, seams, mounts). Note: use “VPAM-APR Level X” for material/panel requirements and “VPAM-BRV VRX” for vehicles; heavy anti-materiel tests (.50 BMG, 14.5×114) are specified via VPAM AND-SoM special tests.

Practical takeaways (clear & enforceable):

Treat NIJ 0123.00 as the projectile/velocity level source and NIJ 0101.07 as the test & pass/fail playbook (BFD + perforation).

Treat VPAM-APR as the material/panel level descriptor (APR Level X = defined projectile + velocity + distance + witness-plate pass/fail). Use VPAM-BRV for whole vehicles/systems.

Never equate levels by name alone. Always specify projectile + mass + reference velocity + pass/fail criterion + conditioning in procurement language.

IntelAlytic note: We analyze test data, map global certification frameworks, and maintain The Armor List, enabling your procurement team to translate level names into enforceable test matrices.

One-line procurement addition (paste into RFPs)

“Specify the exact standard and edition (e.g., NIJ 0101.07; NIJ 0123.00; VPAM-APR Edition 3), require an approved lab test report with ammunition manufacturer/type and lot, conditioning regimen, raw data, and full specimen traceability; for heavy/anti-materiel threats, reference VPAM AND-SoM.”

At IntelAlytic, we help teams make informed decisions by analyzing test data, mapping global certification frameworks, and maintaining the world's most comprehensive ballistic armor database: The Armor List.

Explore specifications, checklists, and side-by-side matrices in our Resources. For product scouting and certification details across the NIJ and VPAM ecosystems, use The Armor List.

Glossary of Key Ballistic Terms

NIJ 0123.00 — NIJ’s specification that defines ballistic protection levels (HG1, HG2, RF1, RF2, RF3) and the exact test threats/ reference velocities used across NIJ programs.

NIJ 0101.07 — NIJ’s performance & test-method standard for torso body armor. It references NIJ 0123.00 for levels/threats and adds pass/fail criteria, clay-based trauma assessment (P-BFD), conditioning, shot placements, labeling, and specimen traceability.

HG / RF Levels (NIJ) — NIJ’s protection families for handgun (HG1, HG2) and rifle (RF1, RF2, RF3). Examples (per NIJ 0123.00):

VPAM-APR (APR Levels/material tests) — VPAM’s general test guideline for materials (APR). Use “VPAM-APR Level X” (not legacy “PM#” shorthand). APR defines the standard small-arms levels (APR1–APR10 in Edition 3) by projectile, mass, firing distance, and reference velocity; pass/fail is penetration/no-penetration against a 0.5 mm aluminum witness plate (witness plate set 150 ± 5 mm behind specimen). Very heavy anti-materiel threats are handled via VPAM AND-SoM (special tests).

VPAM HVN 2009 (helmets, visors, neck protection) — VPAM guideline for head protection. HVN includes BFD/backface criteria and head-specific injury tolerances that are stricter and fundamentally different from NIJ torso-BFD approaches.

VPAM BSW 2006 (bullet-resistant vests) — Product-specific VPAM guideline for vests; uses APR projectiles but applies vest-specific shot placements and conditions.

VPAM-BRV (bullet-resistant vehicles) — VPAM vehicle/system standard (VR1–VR10). BRV evaluates the system (glazing in mounting position, seams, mounts, multi-hit, obliquity, and weak-point performance).

APR / AND-SoM (VPAM) — APR = the umbrella table of standard test levels (APR1–APR10 in Edition 3). AND-SoM = VPAM’s ammunition/special-test catalog for heavy or non-standard threats (e.g., .50 BMG, 14.5×114); use AND-SoM when specifying non-APR projectiles.

Backface Deformation (BFD) / P-BFD — The clay indentation caused by a non-perforating hit. NIJ 0101.07 uses clay BFD (44 mm soft-armor limit) to limit blunt trauma. VPAM APR generally uses witness-plate penetration (HVN uses helmet-appropriate BFD limits).

Witness Plate — 0.5 mm aluminum sheet used in VPAM-APR tests, positioned 150 ± 5 mm behind the specimen to register penetration/no-penetration.

Ballistic Threat — The specific projectile, mass, and reference velocity used for testing (e.g., 9×19 mm FMJ at 415 ± 10 m/s; 7.62×51 M80 at 847 m/s). Always specify the projectile manufacturer/type + lot in procurement language.

AP (Armor-Piercing) Rounds — Projectiles with hardened cores (steel/tungsten) intended to defeat armor. NIJ explicitly covers AP at RF3 (.30-06 M2 AP). VPAM APR includes AP/API threats in upper APR levels (see APR8–APR10 and AND-SoM for heavier AP).

MSC (Mild-Steel-Core) — A bullet with a mild-steel core (e.g., 7.62×39 MSC used in NIJ RF1/RF2 threat sets). NIJ 0123.00 prescribes ammunition audits to control lot variability for such rounds.

Conditioning — Pre-test environmental and mechanical exposure (heat, humidity, flex) intended to simulate field wear before live-fire assessment. Mandatory and defined in NIJ 0101.07; in VPAM, conditioning, temperature, and angle are specified in the test setup and may be applied as required.

Obliquity — Angled (non-normal) impact testing to evaluate edge, seam, and integration weakness — commonly used in VPAM-BRV and included in expanded NIJ plate shot placements.

Explore more than 400+ Glossary Terms in Ballistic Resistant Products and Materials in our comprehensive Database here.

The Armor List Glossary

Want to Dive Deeper?

✔️ Compare VPAM and NIJ specs side-by-side

✔️ Explore threat types, testing methods, and armor specs

✔️ Search certified manufacturers and products

Explore The Armor List

Contact Us for support with global testing and certification strategy

Explore IntelAlytic Services

Follow us on LinkedIn for daily tips and resources