Decoding the Ballistic Resistant Shield Market

Ballistic shields have undergone a remarkable transformation. They have gone from rudimentary protective devices to state-of-the-art tactical gear. As a result, they have become invaluable tools for military and law enforcement personnel.

Join us in this article as we explore the evolution of modern shields with IntelAlytic's expertise. We'll cover the origins, anatomy, and real-world applications of ballistic shields. Dive into the impact of the FBI's RFP15F06723R0000173 ($45 Million RFP for Ballistic Resistant Shields / Pistol Resistant Shields / Rifle Resistant Shields) and its influence on the current market. Discover evolving protection standards, key market players, and future trends in the dynamic landscape of ballistic-resistant shields.

As industry insider’s, IntelAlytic is ready to provide in-depth market insights and guidance. Join us as we decode the fascinating world of ballistic shields and uncover the strategies for success in this ever-evolving defense and personal protective equipment (PPE) industry.

Here is an outline of the topics covered in this blog:

Ballistic Shield Facts & Fiction

Decoding Ballistic Shields with IntelAlytic Insights

Anatomy of a Ballistic Shield

Ballistic Shields in the Field

Federal Agency Engagement: The FBI RFP Spotlight

The FBI RFP (Request for Proposal) Spotlight

Influence on the Ballistic Shield Market

Evolving Protection Standards: From Level IIIA Shields to Level III Shields

Ballistic Shield Key Market Players

What Lies Ahead in the Dynamic Landscape of the Ballistic Shields Market?

The evolution of shields has been propelled by advancements in materials technology and innovative design. This has resulted in shields that can withstand high-powered rifle rounds, yet remain light and maneuverable. Modern-day shields come equipped with auxiliary components such as viewports, lights, and camera systems. Further enhancing the situational awareness and communication of frontline operations.

The compelling narrative of ballistic shields is steeped in a rich blend of factual developments and a dose of fiction. These tools, originally conceived as basic defensive apparatuses, have evolved to become advanced tactical gear. Capable of thwarting formidable threats while remaining surprisingly lightweight and maneuverable.

Ballistic Shield Facts & Fiction

Facts about Ballistic Resistant Shields

Key to this metamorphosis has been the revolutionary strides in material science. Traditional, heavier materials such as steel have been supplanted by advanced composites like ultra-high-molecular-weight polyethylene (UHMWPE), aramid fiber (Kevlar), and ceramics. These modern materials enhance the protective capability of shields while reducing their weight.

The innovations in shield design extend beyond material selection, encompassing electronic integration to augment their functionality. Features like viewports amplify field vision in critical situations, while embedded lighting systems can either disorient potential threats or illuminate murky surroundings. More recently, camera systems have been incorporated into shield design, providing a significant leap in situational awareness by allowing for remote monitoring and evaluation of the tactical environment, ultimately aiding in better-informed decision-making.

Shields are not confined to stopping bullets or fragments; their utility extends to various operations. Their size and durability can serve as a strategic distraction, drawing enemy attention and disorienting potential threats. This strategic usage allows for decisive actions during tight windows of opportunity. Shields can also act as versatile tools in physically demanding situations, aiding in lifting heavy obstacles, holding down objects to secure areas, or facilitating entry breaches.

Fiction and Misconceptions of Ballistic Resistant Shields

Moving into the realm of fiction, media, and popular culture often exaggerates the capabilities of ballistic shields for dramatic effect. The notion of shields as impenetrable objects is prevalent, insinuating immunity against any force. However, while incredibly resilient, shields are designed to withstand specified threat levels, and powerful weapons could potentially breach their defenses.

The portrayal of the weight and maneuverability of shields is often skewed. Fictional representations often show characters carrying large shields without any difficulty.

This gives the wrong impression that these shields are easy to manage. In reality, using these shields is a physical challenge. Although modern ballistic shields are lighter than their historical counterparts, they still require significant strength and training to be used effectively.

Misconceptions about ballistic shield standards are widespread. The NIJ 0108.01 standard, often claimed to be shield-specific, is a generalized standard for ballistic-resistant materials, not specifically intended for shields. Consequently, claims of product certification to this standard are misleading as there is no established compliance testing program to verify such assertions. Products can be tested by the standard, but outright certification is not attainable.

The new ASTM E3141/E3141M-23 (standard aims to rectify this longstanding misunderstanding by providing more detailed and specific guidelines for ballistic shields. This new standard will refine product claims to increase transparency and accuracy in the industry. It will ensure that users receive accurate information about the shields they deploy.

The use of ballistic shields in law enforcement and military operations is undisputed. Despite the mix of truth and fiction that often accompanies them, their importance is undeniable. Offering an optimal balance between protection and mobility, they have become a critical asset for frontline personnel. As technological advancements continue to shape shield design and effectiveness, the future of ballistic shields promises exciting possibilities for enhanced safety and tactical efficacy.

Decoding Ballistic Shields with IntelAlytic Insights

At IntelAlytic, we have a mission: to deliver tailored, data-driven solutions and support to the defense and public safety market. Taking complex topics and simplifying them to enable our clients to achieve long-term sustainable growth. Our partners, Mike Bundy and John Atkins bring nearly 40 years of combined deep-seated industry experience and invaluable expertise in personal protective products including ballistic resistant shield design, engineering, manufacturing, and large-scale deployment for military and law enforcement sectors.

Their rich legacy in hard armor research and development serves as the foundation of our commitment to the intricate world of ballistic protection. Guided by their expertise, we strive to provide incisive analysis and offer insightful industry perspectives, ensuring that our clients and partners gain a clear understanding of this field.

Through comprehensive analysis, we break down complex concepts and navigate the ever-changing dynamics of ballistic protection. Our goal is to empower businesses and professionals with valuable information, enabling them to make informed decisions and drive innovation in this critical defense sector.

By leveraging our expertise and deep understanding of ballistic protection, we offer strategic guidance and support to small and medium-sized businesses (SMBs), helping our clients navigate the rapidly shifting landscape of the Defense Industrial Base. Whether it's a question of compliance with domestic and international standards, laws, and regulations or a matter of developing and commercializing products for public safety and defense applications, we equip our clients with the knowledge and tools they need to succeed.

With a relentless dedication to unraveling complexities, understanding challenges, and providing forward-thinking insights, IntelAlytic equips businesses with the knowledge and tools needed to thrive in this rapidly evolving landscape.

We invite you to delve deeper into our professional journeys and the expertise we bring to the table. Visit the bios of Mike Bundy and John Atkins to learn more about IntelAlytic’s founders, who have compiled this and other valuable insights specific to defense and public safety markets.

Schedule a meeting to learn more about our services or subscribe to our newsletter to stay ahead of the curve.

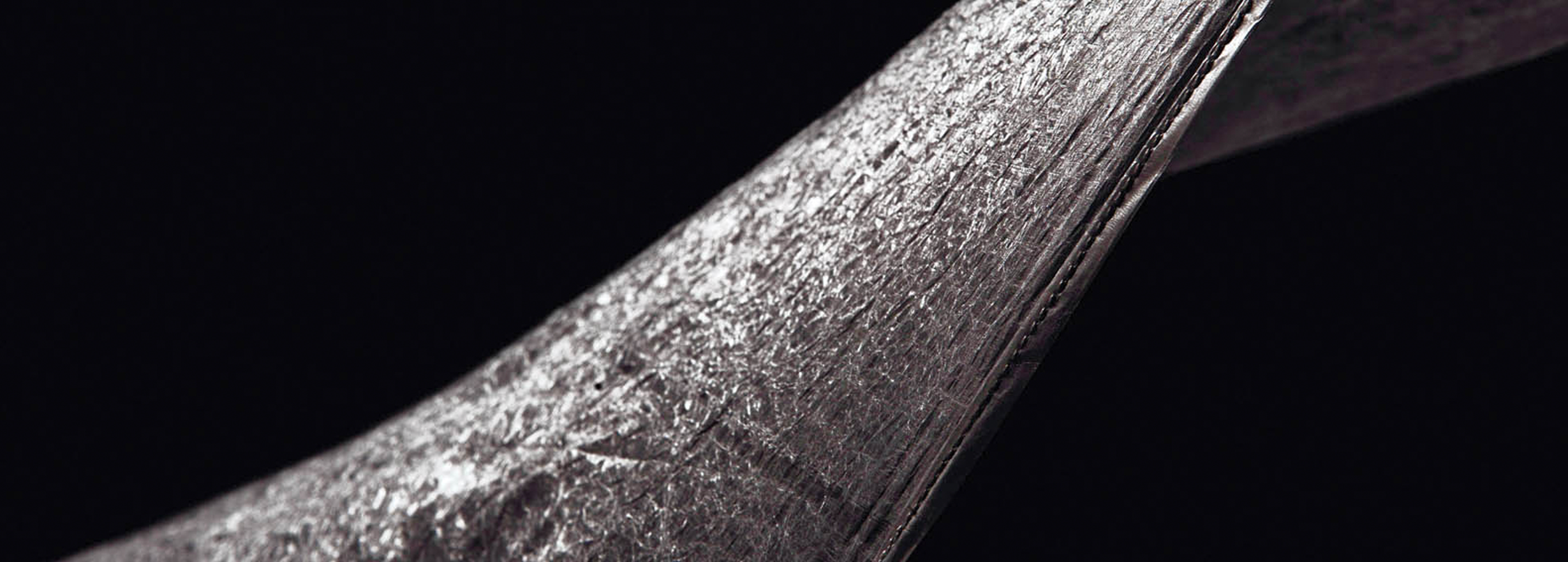

DSM Dyneema® UHMWPE fiber is 15 times stronger than steel and 40 percent stronger than aramid, yet still floats on water. This combination of strength and lightness makes it an ideal material for ballistic shields. Photo: DSM Dyneema.

Anatomy of a Ballistic Shield

To comprehend the intricacies of a ballistic shield, one must delve into its material composition, design philosophy, and engineering considerations. These intertwined factors shape the performance of a shield, ultimately determining its protective capabilities.

UHMWPE (Ultra-High-Molecular-Weight Polyethylene)

The bedrock of most contemporary ballistic shields is constructed from layers of ultra-high-molecular-weight polyethylene (UHMWPE). UHMWPE is a type of thermoplastic polyethylene that offers a high strength-to-weight ratio, establishing it as an ideal material for ballistic protection. Known for its lightweight properties, extraordinary impact resistance, and significant durability, UHMWPE is a staple in modern shield construction.

Aramid Materials

Another crucial component in the make-up of a ballistic shield is aramid fiber, often recognized by its brand name, Kevlar. This heat-resistant and high-strength synthetic fiber has been the cornerstone of the armor industry for decades due to its exceptional tensile strength, impressive heat resistance, and superior impact absorption capabilities. Kevlar provides a tough yet flexible layer that disperses the energy of an incoming projectile, thereby minimizing its penetrative power.

Ceramics

Ceramics also play an indispensable role in modern rifle-resistant shields. Characterized by their high hardness, ceramics help deform or break incoming projectiles, consequently reducing their penetrative capabilities. The ceramics used in shields are typically constructed from materials like alumina, boron carbide, or silicon carbide. They are commonly used in tandem with backing materials like UHMWPE or Kevlar, which catch the fragments and further absorb the impact energy.

Steel

While not as commonly used in modern shields due to its weight, steel remains an option for certain applications. Its high tensile strength and durability provide robust resistance against various threats. Steel shields are often used in scenarios where weight is not a critical factor, and higher levels of protection are needed.

Other Ballistic Resistant Materials

Beyond the materials mentioned above, various other ballistic-resistant materials may be used in the construction of a shield, including different types of composites, plastics, and metals. These materials are chosen based on their specific properties, including their strength, weight, and ability to absorb and disperse energy. It is the synergistic combination of these materials that ultimately determines a shield's ability to resist ballistic threats effectively.

Understanding these materials and their unique properties provides insight into the intricate world of ballistic shield manufacturing, a testament to the advancements in material science and engineering aimed at safeguarding lives.

Material Science and Composition

These materials are meticulously layered together, with each layer playing a critical role in enhancing the shield's overall performance. The result is a well-orchestrated ensemble that strikes a harmonious balance between weight and protective capability, making the shields a reliable asset in high-risk scenarios.

Additionally, the manufacturing process of these shields involves stringent quality checks and rigorous testing to ensure they meet and exceed the necessary safety standards. Tests typically involve firing various calibers of bullets at the shields and assessing their resistance to penetration and back-face deformation. The result is a highly reliable piece of protective equipment that can withstand the immense pressures of frontline duty.

In the hands of skilled and experienced operators, these shields not only provide essential protection but also contribute to mission success. They can protect against a variety of threats, from bullets and shrapnel to melee attacks, all while allowing the user to maintain maneuverability and operational readiness.

The engineering of ballistic shields extends beyond material selection and layering. Considerations also include an ergonomic design for ease of use, the field of view, the inclusion of a viewport for visibility, ambidextrous handle systems for adaptability, lighting systems for low-light operations, and much more. These additional features are all thoughtfully integrated to enhance utility and effectiveness in the field.

As we continue to advance in technology and understanding of materials and their properties, the evolution of ballistic shields is an ongoing process. The goal remains constant: to provide maximum protection while minimizing weight and maximizing mobility, ensuring our law enforcement and military personnel are equipped with the best possible tools to keep them safe in the line of duty.

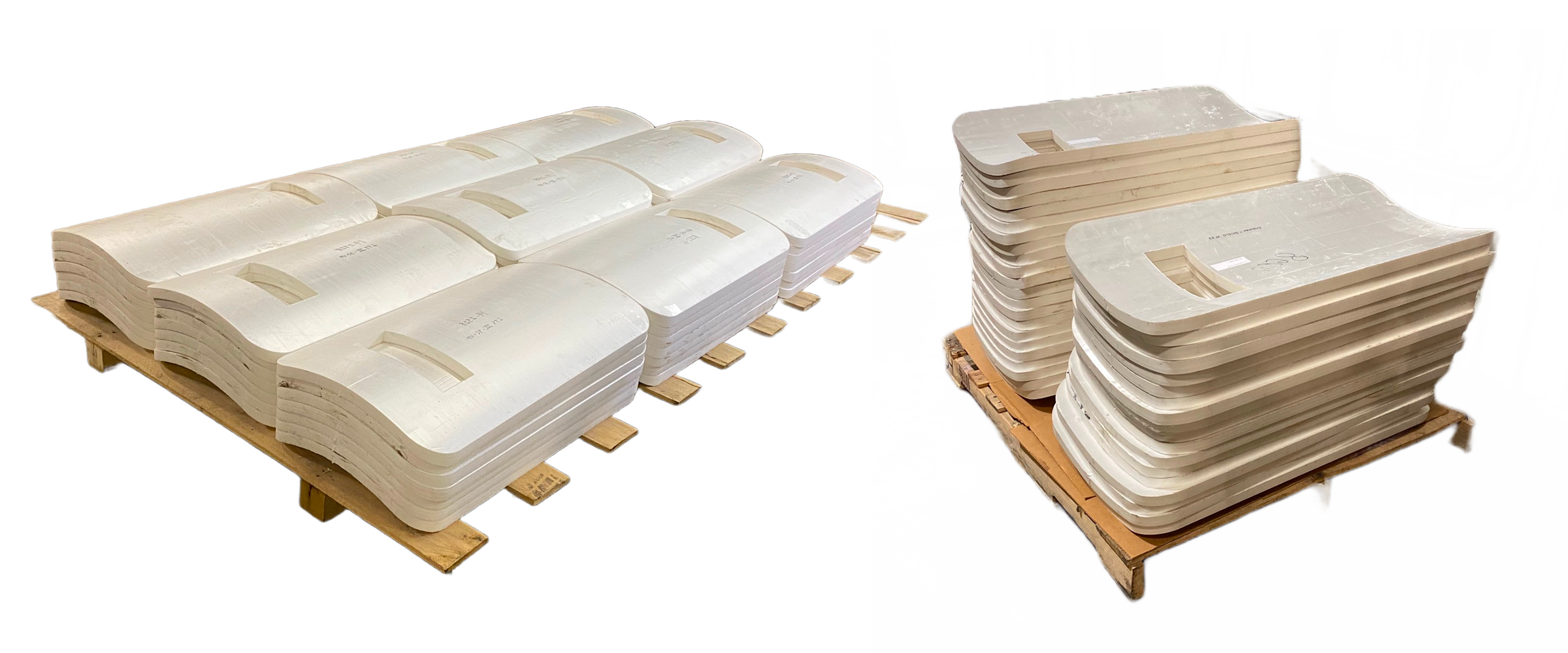

Ballistic Shield Construction

Ballistic shields are crafted utilizing a variety of materials and manufacturing techniques to ensure optimal performance. As mentioned above, the materials that go into these life-saving products are all key to providing an effective and well-performing product.

It is important to note that material science is only one part of a winning protective platform. The key to success is the material configuration, processing techniques and equipment, and quality control elements of a successful manufacturer.

Design Considerations in Ballistic Shield Construction

Design considerations are a key aspect of the construction of ballistic shields, as the usability and effectiveness of a shield can be drastically impacted by its design. Both ergonomics and the integration of user feedback play vital roles in the design phase.

Ergonomics is an important factor in design considerations as shields need to be easy to handle and maneuver, especially in high-stress environments. The shield's weight distribution, handle placement, and overall dimensions are carefully designed to enhance user comfort and efficiency. The shield’s size and shape are also optimized to provide the best coverage while maintaining ease of movement.

User feedback is another crucial element in designing ballistic shields. Direct input from field users helps manufacturers understand their needs better and can result in design improvements. From the positioning of the viewing windows to the need for lightweight designs or the incorporation of additional features like lights and bezels, user feedback has been instrumental in the evolution of ballistic shield design.

Material Configuration

Ballistic shields are constructed using a diverse range of materials, each playing a critical role in the shield's overall performance. These materials include ballistic fabrics, coverings, handles, pads, windows, bezels, lights, and additional accessories.

The type and configuration of materials utilized directly affect the desired level of protection. For example, certain shields may include a thin ceramic layer on the strike face to counter rounds that typically penetrate composite armor, such as the M855 green tip. While these shields tend to be heavier, they offer increased protection beyond what an all-composite shield can provide.

Additionally, the incorporation of windows in ballistic shields presents unique challenges. Level III ballistic windows typically combine glass and composites, increasing weight. In contrast, Level IIIA windows generally consist of lightweight polycarbonate, which offers both protection and reduced weight.

Processing Techniques and Equipment

Manufacturing a ballistic shield requires specific processing techniques, and the type of equipment used directly correlates with the shield's desired protection level. Some techniques include the use of low-pressure vacuum/oven systems, high-pressure pressing, and other specialized machinery.

Level IIIA shields, for instance, may undergo processing in a low-pressure vacuum/oven system. This method helps eliminate the need for additional post-cure work, allowing the shield to move directly to the finishing stage after curing.

On the other hand, constructing a Level III shield may require high-pressure pressing. This process often involves shaping through cutting on a waterjet, CNC machine, saw, or other machining techniques to achieve the desired form after curing.

Materials such as ceramics and composites/aramids are consolidated and cured using ovens or autoclaves. The pressure applied during these processes serves to consolidate the materials, ensuring they bond correctly and maintain their structural integrity under duress. Some materials, like Endumax or Tensylon, can achieve excellent ballistic performance even at very low processing pressures. Other materials might necessitate high-pressure processing achieved by placing the build in a hydraulic press exerting thousands of pounds per square inch.

Quality Control Elements in Manufacturing

Quality control is an integral part of manufacturing ballistic shields. Essential considerations such as hardware harness, mounting hole coverage, and window overlap with the composite must be meticulously evaluated to prevent potential failure points in the shield's structure. Furthermore, maintaining the traceability of raw materials from the finished good back to the initial purchase order placed to the raw material manufacturer is a vital aspect of quality control.

Quality control also involves recording data during the processing stages, such as temperature and pressure during the cure cycle, to verify conformance to the requirements for the shield being processed.

The process of manufacturing ballistic shields is a highly intricate one, involving careful material selection, precise processing techniques, and stringent quality control considerations. By understanding these elements, manufacturers and users can better appreciate the complexities involved in producing reliable and efficient ballistic shields.

Maintenance and Durability of Ballistic Shields

Maintenance and durability are other pivotal aspects of ballistic shields. These shields are designed to withstand harsh environments and extreme conditions, so their durability is of paramount importance. The materials used, including high-strength composites and aramids, are selected for their resilience and longevity, providing consistent protection over the shield's lifespan.

In terms of maintenance, ballistic shields are generally designed to require minimal upkeep. However, regular inspections are essential to ensure their protective capability remains uncompromised. This could involve visual checks for surface damage, structural integrity assessment, and ensuring all components, such as handles, viewports, and accessories, are securely fastened and functioning properly. Manufacturers’ recommendations should always be consulted when maintaining and caring for a ballistic shield.

The durability and lifespan of a ballistic shield are also influenced by its storage conditions. Shields should be stored in cool, dry conditions away from direct sunlight, which can degrade certain materials over time. With proper care and handling, a ballistic shield can provide reliable protection for a substantial period.

By considering these factors during design and construction, manufacturers can produce ballistic shields that not only meet the stringent performance requirements but are also user-friendly, durable, and require minimal maintenance. The result is a product that is not just a tool but a trustworthy partner for those in the line of duty.

Ballistic Shields in the Field

Ballistic shields serve as formidable companions to the brave heroes who protect and serve us. Shields are often used as the first line of defense in high-risk scenarios. They have been carefully designed to provide the best possible protection while still allowing for mobility.

They accompany law enforcement officers, rescue teams, and military personnel, protecting them as they navigate dangerous situations and ensuring they can perform their duties effectively. With an ever-evolving threat landscape, innovations in shield design continue to target enhanced user mobility, visibility, and overall protection.

Image Credits: Patriot 3 Ballistic Shields Deployed

Law Enforcement Applications

In the realm of law enforcement, the indispensability of ballistic shields is exemplified in numerous real-world scenarios. Consider the high-pressure Uvalde shootout in Texas. Officers were able to protect themselves behind a ballistic shield while engaging with the active shooter, minimizing potential casualties.

Similarly, in 2016 during a tragic shooting in Dallas, Texas, that claimed the lives of five officers, a ballistic shield proved instrumental in saving several others. Officers used the shield to approach the shooter's position under the barrage of bullets, ultimately neutralizing the threat. These incidents underscore how ballistic shields serve as active tools for neutralizing threats while minimizing officer casualties in various law enforcement scenarios, from SWAT operations to active shooter situations.

Rescue Operations

Ballistic shields also play a crucial role in rescue operations. For instance, in 2018, a dramatic event unfolded in Denver, Colorado, where officers used a ballistic shield to rescue a man held at gunpoint. The shield provided the necessary cover to approach the scene and successfully evacuated the victim amidst the imminent threat of gunfire. This incident underscored the vital role of ballistic shields in enabling law enforcement personnel to conduct lifesaving rescue operations under direct threat.

Military Operations

Ballistic shields serve a critical role in military operations as well. Given the unpredictability and high-risk nature of these scenarios, shields provide crucial protection against armed opposition. Designs cater to specific military needs, such as lightweight materials for ease of transport during rapid deployments and enhancements like ballistic glass viewports for improved situational awareness.

As the threat landscape continues to evolve, so does the design and functionality of ballistic shields. Innovations continue to enhance user mobility, visibility, and overall protection. Shields today are a combination of advanced materials, versatile features, and innovative designs. Shielding our heroes who serve in law enforcement, rescue operations, and the military.

Shield Training Programs are a Necessity, not just an Option

The tactical significance and life-saving potential of ballistic shields highlight the indispensable need for comprehensive training. Proper use of a ballistic shield can mean the difference between life and death in high-risk situations. It is essential that officers and military personnel who handle these shields receive extensive training.

Comprehensive Training Programs

Numerous training programs exist that aim to prepare law enforcement and military personnel for the diverse scenarios where shields may be employed.

These programs focus not only on the physical skills needed to wield a shield but also on mental preparedness and strategic thinking. Trainees learn essential skills such as: - Optimal shield positioning - Moving while carrying the shield - Engaging threats from behind the shield - Working as a team when multiple shields are in use.

Physical and Mental Preparedness

Physical training ensures personnel has the strength and endurance to carry and maneuver a shield, often weighing up to 20 pounds, over extended periods. Mental preparedness training focuses on enabling shield bearers to make split-second decisions under intense pressure.

Team Coordination and Communication

In many scenarios, ballistic shields are used in conjunction with team strategies, requiring seamless coordination and communication. Effective training includes techniques for shield formations, transitions, and tactics that can adapt to the fluid dynamics of live threat scenarios.

Real-world Scenario Simulations

Training programs often include real-world scenario simulations to allow trainees to apply their learned skills in a controlled environment. This could involve active shooter situations, hostage scenarios, or riot control, each presenting unique challenges and requiring specific shield tactics.

Ongoing Skill Development

Ongoing training and skill refinement are essential, ensuring personnel can adapt to new threats, tactics, and shield technologies. The life-saving potential of a ballistic shield is only fully realized when it's in the hands of a well-trained individual.

By investing in comprehensive, up-to-date shield training programs, we ensure that our law enforcement and military personnel are equipped with the knowledge, skills, and confidence to use these tools effectively, safeguarding their lives and those they are sworn to protect.

Federal Agency Engagement: The FBI RFP Spotlight

Federal agencies are some of the most prominent and critical end-users of ballistic shields in the United States. Organizations like the Federal Bureau of Investigation (FBI), Drug Enforcement Administration (DEA), Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF), and U.S. Marshal Service frequently use ballistic shields in their high-risk operations and missions. Shields are widely used among special operations teams within these agencies, where they play a crucial role in ensuring officer safety.

Who is the key buyer driving this current massive RFP buy?

Yes, $45+ Million for ballistics shields is MASSIVE.

The FBI is the main federal investigative agency in the United States. It has authority over violations of over 200 types of federal crimes. Their tactical teams, like the Hostage Rescue Team (HRT) and SWAT (Special Weapons and Tactics), are trained in the use of tactical equipment, including ballistic shields, to execute high-risk operations that require specialized skills.

Who is in support of the RFP development and primary buyers with the FBI?

Drug Enforcement Administration (DEA)

The DEA enforces the controlled substances laws and regulations in the U.S. Their Special Response Teams (SRT) often use ballistic shields in their operations for protection during raids or while handling potentially violent individuals. This is especially true, in the context of the drug trade which often involves armed resistance.

The U.S. Marshals are the nation's oldest federal law enforcement agency, responsible for the protection of the federal judiciary, apprehension of federal fugitives, managing and selling seized assets, housing, transporting federal prisoners, and more. Their Special Operations Group (SOG) often utilizes ballistic shields in high-threat and high-risk operations.

The ATF is a law enforcement agency within the U.S. Department of Justice that protects communities from violent criminals, criminal organizations, illegal use, and trafficking of firearms, and more. The ATF Special Response Team (SRT) uses ballistic shields in their operations to provide personal protection in high-risk situations.

Catalysts for Technological Advancements

The stringent operational requirements and high standards of federal agencies often catalyze advancements in shield technology. These agencies demand cutting-edge equipment that meets or exceeds a strict set of criteria, pushing manufacturers to innovate and improve their products constantly.

The FBI Request for Proposal (RFP) Spotlight

A prime example of this is the detailed analysis of the FBI's recent request for proposal (RFP) for ballistic shields. This document provides a comprehensive overview. It outlines the desired specifications, contract terms, and overall expectations the Bureau has for modern ballistic shields.

Specifications can include factors such as minimum required protection levels (typically, at least NIJ Level IIIA), weight limitations, dimensions, viewport construction, and lighting systems. Contract terms might outline delivery timelines, warranty periods, and pricing arrangements.

The RFP is more than a shopping list for the FBI; it's a roadmap for the industry, illustrating the high standards expected of modern ballistic shields and the essential characteristics that a quality shield should possess.

CURRENT FBI REQUEST FOR PROPOSAL

RFP15F06723R0000173: Ballistic Resistant Shields / Pistol Resistant Shields / Rifle Resistant Shields

GENERAL INFORMATION

Notice ID: RFP15F06723R0000173

Contract Opportunity Type: Combined Synopsis/Solicitation

All Dates/Times are: (UTC-05:00) CENTRAL STANDARD TIME, CHICAGO, USA

Updated Published Date: Jun 09, 2023, 02:12 pm CDT

Original Published Date: May 17, 2023, 11:24 am CDT

Updated Date Offers Due: Jul 27, 2023, 02:00 pm CDT

Original Date Offers Due: Jun 30, 2023, 03:00 pm CDT

Inactive Policy: 15 days after the date offers are due

Updated Inactive Date: Aug 11, 2023

Original Inactive Date: Jul 15, 2023

CLASSIFICATION

Original Set Aside: Total Small Business Set-Aside (FAR 19.5)

Product Service Code: 8470 - ARMOR, PERSONAL

NAICS Code: 315990 - Apparel Accessories and Other Apparel Manufacturing

Influence on the Ballistic Shield Market

These RFPs and their stringent requirements significantly influence the ballistic shield market. They drive innovation, shape manufacturing practices, and set benchmarks for quality and performance. Suppliers must adapt to these evolving demands to remain competitive and relevant in the market.

Trend Forecasting and Product Development

Examining and understanding the trends and requirements outlined in federal RFPs helps manufacturers forecast the future needs of these agencies. It enables them to invest in the research and development necessary to meet and exceed these needs. Helping to position them to win future contracts and continue to supply these essential tools to those who need them most.

Flow-Down Effect on Other Agencies

The influence of federal agencies on ballistic shield technology extends beyond their specific operational scope. Federal entities such as the FBI, ATF, DEA, and U.S. Marshal Service often set strict standards. This creates a 'flow-down' effect, where these standards trickle down to state and local law enforcement agencies. These smaller entities often look to federal agencies for guidance and tend to adopt similar standards and requirements.

This flow-down effect also means that advancements in shield technology prompted by federal demands eventually benefit a much broader user base. Consequently, innovations and improvements that are initially developed to meet the needs of federal agencies end up elevating the overall quality and performance of ballistic shields across the entire law enforcement spectrum.

Are other federal agencies looking to buy off this program lead?

The DHS is a cabinet department of the U.S. federal government with responsibilities in public security. Agencies under the DHS such as the Customs and Border Protection (CBP), Immigration and Customs Enforcement (ICE), and others have tactical units that utilize ballistic shields for various law enforcement activities.

As part of U.S. Customs and Border Protection, the Border Patrol's mission is to prevent the illegal entry of individuals and goods into the U.S. Their Special Operations Group (SOG) could potentially use ballistic shields during operations in high-risk areas.

The Secret Service protects national leaders and their families and investigates financial crimes. Their Counter Assault Team (CAT) and Emergency Response Team (ERT) could potentially use ballistic shields during their operations, especially in high-risk scenarios.

The U.S. Park Police provide law enforcement services to designated areas within the National Park Service. Their SWAT team may use ballistic shields in situations requiring a tactical response.

The Coast Guard is responsible for maritime safety, security, and stewardship. The Coast Guard's Maritime Safety and Security Teams (MSST) and Maritime Security Response Teams (MSRT) could potentially use ballistic shields during boarding operations and other high-risk scenarios.

Evolving Protection Standards: From Level IIIA Shields to Level III Shields

Federal agencies are increasingly emphasizing the need for shields that can withstand rifle rounds, rather than just those for handguns. This is a significant trend in their Request for Proposal (RFPs).

Traditionally, the standard for ballistic shields has been to meet NIJ Level IIIA, which is rated for .44 Magnum and .357 SIG handgun rounds.

However, the evolving threat landscape has led to an increased focus on Level III shields, which are designed to stop rifle rounds such as the 7.62x39mm FMJ lead core, 5.56x45mm NATO rounds, and other high-powered, non-armor-piercing ammunition like the M855 and M193. This shift reflects the increasing prevalence of high-powered firearms in both domestic and international threat scenarios.

Advances in shield technology and materials are emerging in response to the challenge posed by high velocity, penetrating rounds. Shields must be able to stop powerful rounds while still keeping their integrity intact after impact. Additionally, they must be able to provide multi-hit protection incase of ongoing rounds being fired.

This trend towards Level III protection has substantial implications for ballistic shield manufacturers. To meet this rising demand, manufacturers must invest in advanced materials and construction techniques capable of withstanding these more powerful rounds, all while still maintaining a manageable weight and maneuverability for the shield operators.

The importance of staying ahead of this trend cannot be overstated. Manufacturers that can successfully navigate this shift towards Level III protection will be well-positioned to meet the evolving needs of federal agencies, and subsequently, law enforcement agencies at all levels.

Market Overview of Ballistic Shield Manufacturers

In the bustling sector of ballistic shield manufacturing, innovation, competition, and quality assurance are the driving forces that shape the landscape. This market attracts a diverse mix of entities, each bringing its unique strengths, perspectives, and strategies to the forefront.

In this unbiased overview, we aim to shed light on the industry's various stakeholders, dividing them into three distinct categories: Key Competitors, Secondary Competitors, and Wild Card Competitors. These groups each contribute uniquely to the dynamics of the industry, creating a rich and varied market.

Key Competitors

The front-runners in the market fall under this category. Their influence is prominent, and they consistently set benchmarks for quality and performance in the sector. These organizations leverage their extensive experience, robust R&D capabilities, and wide-ranging product portfolios to steer the evolution of ballistic shield technologies and shape market trends.

This partnership merges Hardwire's expertise in protective armor, widely employed by the U.S. military, with Safariland's renowned presence in the law enforcement community. They offer an extensive range of ballistic shields.

Paraclete/Point Blank Armor

Point Blank is one of the world's leading manufacturers of body armor, with its subsidiary, Paraclete, known for producing durable and reliable body armor. Their combined proficiency in ballistic shields is significant.

Celebrated for its innovative and custom tactical equipment, Tyr Tactical blends cutting-edge materials with ergonomicc design in their ballistic shield offerings.

Known for its broad range of ballistic protective products, BlueRidge Armor's shields stand out for their advanced materials and functional designs.

Protech is a leading brand under the Safariland Group, known for its innovative and high-performance ballistic and tactical products. Their body armor solutions, including ballistic shields, cater to the diverse needs of law enforcement, military, and security professionals globally.

Secondary Competitors

Adding an extra layer of diversity to the market are these entities. Although they might not command as large a market share as the key competitors, their unique offerings and innovative approaches cater to specific segments of the customer base, thereby enhancing market competition and variety.

Known for a wide range of armor protection solutions, including ballistic shields, HighCom Armor enjoys a reputation for quality and innovation.

United Shield specializes in protection equipment for military, law enforcement, and security agencies. Their collaboration with Point Blank enriches their product offering.

A global provider of protective solutions, Tencate is recognized for its composite and ceramic-based armor products, including ballistic shields.

This company specializes in tactical and ballistic protection equipment, with a particular focus on shield-based solutions, including mobile and flexible options.

Known for their patented Rifle-Shield technology, Baker Ballistics offers advanced ballistic shields that can withstand high-caliber threats.

NP Aerospace

A company that provides a wide range of tactical gear, including ballistic shields. Their products are well-reviewed by the law enforcement community.

Wild Card Competitors

Emerging or diversifying entities that have the potential to disrupt the current market dynamics are grouped into this category. They often bring novel solutions to the table and might introduce shifts in the market's status quo. Each is a wild card factor as the situation with the FBI RFP can cause key players in other well-established markets like flexible soft armor, rifle protective hard armor, or vehicle and platform armor to jump into the race.

An industry leader in developing lightweight, high-strength composite materials. They leverage this expertise to produce top-grade ballistic shields.

Hesco Armor

Known for their comprehensive line of body armor solutions. Hesco Armor has a reputation for producing high-quality, durable protective gear, including ballistic shields. Their shields are trusted by military and law enforcement personnel across the globe.

A provider of a wide range of tactical gear, including ballistic shields, RTS Tactical's products are new to this space, and it is unknown if they are the Manufacturing source or a private label OEM player. At the time of this publication, we were unable to precisely verify the key details behind this company and its products.

Armor's Choice

Specializes in developing innovative armor solutions for law enforcement and military personnel. They have a strong reputation for creating durable, lightweight, and effective ballistic shields that are designed to meet the demanding needs of frontline defense and security forces.

We analyze the competitive landscape of the market. Primary and secondary manufacturers raise the bar by using innovative design philosophies, advanced manufacturing techniques, and rigid quality control systems. Their collective contributions are shaping the future of ballistic shield technology and have a profound influence on both national and international safety standards.

Behind the Scenes, we Explore the Unseen Heroes

At the core of the ballistic shield market, there are a series of indispensable players that ensure the final product’s efficacy, durability, and performance. These entities include the suppliers of high-performance materials and the laboratories that meticulously test these products to ensure they meet or exceed the highest safety and performance standards.

Image Credit: Honeywell Industrial Spectra Fibers

Advanced Materials Suppliers

Dyneema, a leading manufacturer of ultra-high molecular weight polyethylene (UHMWPE), is renowned for being incredibly strong yet lightweight. This makes it a preferred material for ballistic shield construction.

Spectra fiber, another form of UHMWPE, is renowned for its strength and lightness. It is frequently used in the fabrication of ballistic-resistant materials, including shields.

Is a high-performance polyethylene material. It is known for its impact resistance and energy absorption capabilities. These features make it suitable for use in ballistic shields.

Teijin Endumax is an ultra-high molecular weight polyethylene product. It is known for its durability and lightweight. These qualities make it a great choice for creating ballistic-resistant materials.

Honorable Mentions

Barrday is a leading advanced material solutions company. They produce a range of composite materials for body armor and ballistic shields.

Industrie Bitossi is a leading international industrial ceramics group based in Italy. They specialize in advanced ceramic materials for armor. This armor is supplied to both military and public safety sectors.

CoorsTek is a significant player in the ceramics industry. Their aluminum oxide (Al2O3) ceramics offer a balance of strength and weight, making them suitable for use in ballistic shield applications.

Saint Gobain is a major supplier of silicon carbide (SiC) ceramics. Their materials are renowned for their hardness and thermal stability. These properties make them ideal for ballistic shield applications.

These suppliers represent the heart of the ballistic shield market. Their continued investment in research and development improves the properties of their materials and pushes the boundaries of what's possible in ballistic shield technology.

Notable Support and Component Materials Suppliers

Iten Defense: is renowned for its patented ballistic materials and systems. They supply essential components for making various ballistic shields. Iten Defense is a key processing facility for many primary and secondary market players. It features large-scale pressing and high throughput small presses with both low- and high-pressure capabilities.

JNI Armor: is a significant supplier in the transparent armor market. They produce viewports for a variety of ballistic shields, from major suppliers to smaller players.

Fox Fury: As a leader in portable LED lighting, Fox Fury supplies the lights often integrated into ballistic shields. While their products are primarily manufactured in China, they nonetheless contribute significantly to shield functionality.

Elzetta: Specializes in flashlights and mounts frequently used in tactical gear including ballistic shields. ElZetta is a preferred solution due to its commitment to U.S. manufacturing.

Image Credit NTS Chesapeake

Ballistic Testing Laboratories

The laboratories responsible for testing and validating the effectiveness of ballistic shields are integral to ensuring product safety and performance. Here's a brief overview of these key labs:

FBI Redstone Arsenal Ballistic Laboratory: Redstone Arsenal is a U.S. Army post located in Alabama. Home to several testing facilities, including those used for ballistics and impact testing. It plays a crucial role in the testing and validation of military-grade equipment, including ballistic shields.

Aberdeen Ballistic Lab: Located in Aberdeen, Maryland, this lab is an integral part of the FBI's efforts to research and validate ballistic-resistant equipment. The lab performs critical tests that help inform the FBI's purchasing decisions, including their RFPs.

Oregon Ballistics Laboratory: This independent lab, located in Oregon, is an NIJ-approved facility that tests a variety of ballistic-resistant products, including shields. They have a reputation for thoroughness and accuracy in their testing protocols.

NTS Chesapeake: Part of the National Technical Systems (NTS) network, the Chesapeake lab provides a range of testing services, including ballistic and impact testing. Their rigorous procedures ensure that products meet the highest standards of safety and performance.

Honorable Mentions

SMS Laboratories: SMS Laboratories, a leading testing and certification lab, offers services including ballistic and impact testing for shields and other armor products. Their expertise and experience make them a trusted partner for many manufacturers in the sector. They have announced an upcoming NIJ-approved laboratory, further cementing their importance in the sector.

Energetic Test Laboratory: As newcomers to the industry, Energetic Test Laboratory, helmed by a team of seasoned experts in the market and materials, is expected to play a significant role in the ongoing quality and research testing for ballistic shields in the years ahead.

By driving innovation through testing, these labs play a crucial role in advancing the ballistic shield industry, providing much-needed assurance that these life-saving products will function as expected when called upon.

There are Ballistic Testing Standards for a Reason

The National Institute of Justice (NIJ) is the research, development, and evaluation agency of the U.S. Department of Justice. They are heavily involved in setting performance standards for ballistic-resistant equipment, including shields, to ensure they meet the necessary safety requirements.

As a globally recognized leader in the development of standards, ASTM sets the testing and certification standards all ballistic shields must meet, playing a critical role in guaranteeing product quality and efficacy.

The National Institute of Standards and Technology is an agency of the U.S. Department of Commerce, and they are responsible for promoting and maintaining measurement standards in the United States. While they don't directly set standards for ballistic shields, they do work on related fields such as material science, engineering standards, and measurement techniques which indirectly impact the standards and testing procedures for ballistic shields.

What Lies Ahead in the Dynamic Landscape of the Ballistic Shields Market?

With the ever-increasing demand for ballistic shields, there's no denying that the industry is rapidly evolving. With every stride in technological advancement and every breakthrough in material science, we see an intensification of the commitment to creating more effective, reliable, and user-friendly ballistic shields.

The intricate interplay between frontline end-users, manufacturers, material suppliers, and testing labs shapes the industry's landscape. Each entity in this equation brings indispensable expertise and insight that progressively fuels the evolution of ballistic shields.

Manufacturers continue to innovate in response to the ever-changing and increasingly complex nature of threats. Material suppliers relentlessly push the boundaries of science and engineering to develop stronger, lighter, and more efficient materials. Testing labs remain the custodians of quality and safety, assuring the effectiveness and reliability of these life-saving tools. Meanwhile, frontline end-users provide the most valuable feedback of all – real-world experiences that inform design, usage, and performance expectations.

So, as the demand for ballistic shields soars, we can anticipate a continued commitment to improving their design and performance. This is evidence of the industry's commitment to ensuring the safety and protection of law enforcement and military personnel worldwide. Their dedication is remarkable.

Engage with IntelAlytic for Market Insights

To navigate this dynamic landscape effectively, having accurate, timely, and in-depth insights is crucial. At IntelAlytic, we strive to simplify complex topics and bring clarity to your decision-making process. We provide a wealth of services designed to keep you informed about emerging trends, technological advancements, market analysis, and competitive intelligence.

Our cutting-edge research methodologies and expansive industry knowledge allow us to provide insights that are not only comprehensive but also actionable. With IntelAlytic as your strategic partner, you will be poised to understand the present state of the market, anticipate future trends, and make informed decisions that drive your success. If you're in the business of ballistic shields or any other defense or public safety industry segment, subscribe to our newsletter to stay ahead of the game with insightful and actionable market intelligence.

Connect with IntelAlytic

At IntelAlytic, we're not just following trends; we're helping you shape the future. Schedule a meeting to learn more about our services and how IntelAlytic can help you stay ahead of the curve.