2024 Guide to Global Ballistic Standards: Essential Insights for Body Armor

DISCLAIMER: This article is presented based on information available in the public domain. It's essential to recognize that there may be a significant amount of information about ballistic threats, performance, and measurements that remain classified and confidential by various governments and organizations globally. Such classified information, crucial for national security and operational secrecy, cannot be disclosed in this article. Our coverage focuses on publicly available data to comprehensively understand the known global ballistic standards, emphasizing their application in law enforcement, military, and civilian security sectors.

At IntelAlytic, our team is proud to leverage over half a century of combined industry expertise, dedicating ourselves to providing educational resources and deep insights to the defense industrial base and public safety markets. Our leadership team's journey began with building one of America's premier body armor companies and has evolved into establishing and building IntelAlytic. Our mission is to harness professional services and technological advancements to disseminate knowledge and educate industry professionals, researchers, academia, and end users about the ever-progressing global market of life-saving equipment, focusing on compliance and quality.

The Imperative of Understanding Ballistic-Resistant Standards

In today's world, characterized by rapidly evolving ballistic threats and continual advancements in weapons and munitions, understanding ballistic-resistant standards has never been more crucial. This holds both on the front lines and in various urban and battlefield environments across the globe. IntelAlytic's aim with this article is to offer a comprehensive understanding of global ballistic standards, assessing their impact on hard and soft body armor. We aim to ensure law enforcement and military personnel have the critical information for optimal protection.

The Importance of Global Ballistic Standards

Different nations have developed their ballistic standards, each mirroring the unique threats and security challenges inherent to their regions. These standards are far more than mere technical guidelines; they are a testament to a nation's commitment to protecting lives against a spectrum of threats in many environments. From the United States NIJ standards to Europe's VPAM and beyond, each framework is vital for evaluating and ensuring the effectiveness of body armor.

A Comprehensive and In-Depth Analysis

This article represents the most thorough and detailed analysis of current ballistic standards published to date. In the following sections, we delve deep into these various standards, meticulously examining the levels of protection they offer, the specific threats they are designed to counter, and the test velocities involved. Our objective is to provide a comprehensive overview that will serve as an invaluable resource for manufacturers, policymakers, and end-users. By doing so, we aim to facilitate informed decision-making that aligns with specific security needs and threats.

Executive Summary

This article analyzes global ballistic standards, pivotal in shaping body armor for military, law enforcement, and civilian security applications. As threats evolve and weaponry advances, understanding these standards is crucial for ensuring optimal protection in various operational environments. We delve into the nuances of major international standards, including the NIJ (United States), ASTM (United States), UL (United States), VPAM (Europe), TR (Germany), HOSDB (United Kingdom), GOST (Russia), and GA141 (China). Each standard is dissected to reveal its specific protection levels, the ballistic threats they address, and their practical implications in real-world scenarios. This article is designed to serve as a comprehensive resource for manufacturers, policymakers, and end-users, aiding in informed decision-making and highlighting the importance of adapting to the ever-changing landscape of ballistic threats. Through this analysis, we aim to contribute to a deeper understanding of the global standards that dictate the safety and effectiveness of body armor in various settings.

NIJ Armor Standards (United States)

The National Institute of Justice (NIJ) standards in the United States are a cornerstone in body armor certification and performance evaluation. It is a comprehensive framework that categorizes body armor into distinct levels, each designed to protect against specific threats. This standard is pivotal for law enforcement and military applications, protecting personnel against common ballistic threats.

Listing of NIJ Standards

NIJ Standard-0101.06: Current standard for ballistic resistance

NIJ Standard-0101.07: Released in November of 2023, this new standard includes threat levels and testing methods

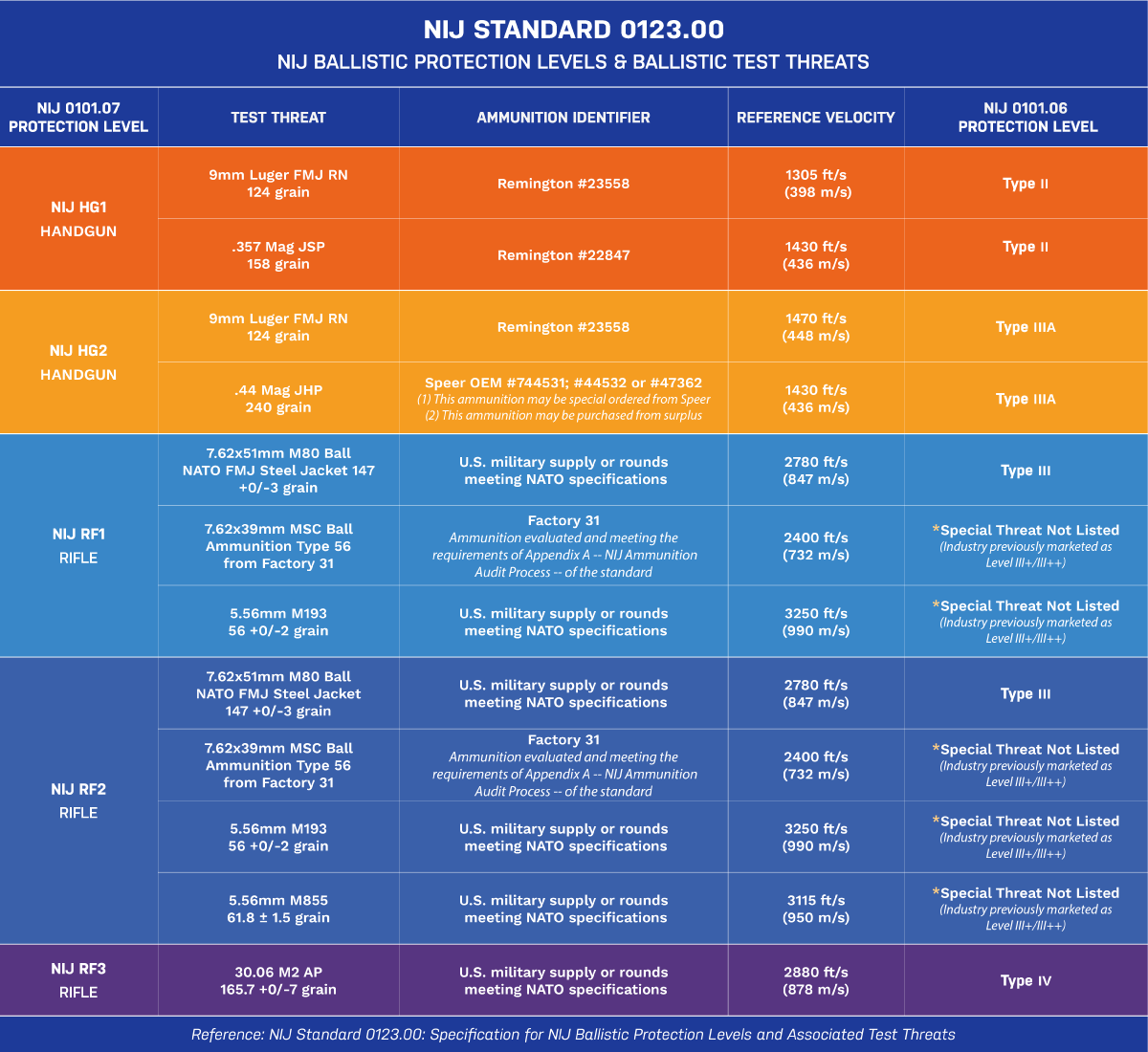

NIJ Standard-0123.00: Released in November of 2023 along with the NIJ Standard 0101.07, this standard outlines the specification for NIJ Ballistic Protection Levels and Associated Test Threats

NIJ Standard 0115.00: Specifics for stab, knife, and spike resistance

NIJ Standard 0104.02: For riot helmets and face shields

NIJ Standard 0108.01: Pertains to ballistic protective materials

NIJ Standard 0106.01: For helmets

NIJ Standard 0117.00: For public safety bomb suit standard

NIJ Standard 0101.06 Overview (United States)

Protection Levels

Type I (Discontinued): Initially designed for protection against .22 Long Rifle Lead Round Nose (LR LRN) bullets and .380 ACP Full Metal Jacketed Round Nose (FMJ RN) bullets. This level was primarily suited for lower-threat environments and is now discontinued, reflecting advancements in ballistic protection needs.

Type IIA: This level protects 9mm and .40 S&W ammunition. Specifically, it includes testing against 9mm FMJ RN bullets at a speed of 373 meters per second (m/s) and .40 S&W FMJ bullets at 352 m/s. Additionally, it encompasses protection against .357 Magnum and 9mm rounds in new and conditioned states, highlighting its adaptability to different wear-and-tear conditions.

Type II: Designed to protect against higher velocity 9mm +P (plus P, indicating higher pressure) and .357 Magnum rounds. It is tested with 9mm FMJ RN bullets at a velocity of 398 m/s and .357 Magnum Jacketed Soft Point (JSP) bullets at 436 m/s. This level balances comfort and protection for law enforcement officers facing moderate threat levels.

Type IIIA: Tailored for high-velocity pistol threats, this level includes protection against .357 SIG FMJ Flat Nose (FN) bullets at 448 m/s and .44 Magnum Semi Jacketed Hollow Point (SJHP) bullets at 436 m/s. Type IIIA armor is well-suited for situations where officers face heavy pistol calibers.

Type III: Specifically designed for high-velocity rifle threats such as the 7.62×51mm NATO FMJ ammunition. This armor level is tested to stop 7.62mm FMJ lead core rifle ammunition with a velocity of 847 m/s. It provides a higher level of protection, making it suitable for tactical situations involving rifle threats.

Type IV: The highest protection level under NIJ Standard 0101.06, designed to withstand armor-piercing rifle threats. Specifically, this level is tested with .30-06 Springfield 166 grain armor-piercing (AP) M2 bullets at 878 m/s. This level is commonly used in high-risk tactical scenarios and by personnel who might encounter armor-piercing rifle ammunition.

Bonus

Type III+/III++

Type III+ and Type III++ designations are not officially recognized within the NIJ 0101.06 standard. They are commonly used in the industry to denote armor capable of stopping specific 'special threats' that exceed the capabilities of standard Type III armor. These special threats often include:

7.62x39mm Soviet (MSC): A standard rifle round used in AK-47 and similar firearms. The MSC (Mild Steel Core) designation refers to the bullet's core composition.

5.56x45mm NATO M193 Ball: A standard U.S. military rifle cartridge known for its high velocity and commonly used in AR-15/M16 rifles.

5.56x45mm NATO M855/SS109: Also used in NATO rifles, this cartridge is known for its steel penetrator tip, designed to penetrate hard targets more effectively.

Key Considerations for Type III+/III++ Armor

No Standardized Protection Levels: Since these levels are not officially recognized, the protection offered can vary significantly between armor manufacturers.

Attention to Test Velocities: It is crucial to examine the velocities at which the armor was tested against these threats. Higher test velocities typically indicate more robust protection against high-speed projectiles.

Laboratory Accreditations: Verify that accredited laboratories tested these armors. Accreditation ensures the reliability and credibility of the testing process and results.

Marketing Claims vs. Actual Performance: Be cautious of marketing claims surrounding these armor levels. Always demand detailed test data and certifications to substantiate any protection claims.

End-User Due Diligence: Users should undertake comprehensive research to understand the specific capabilities and limitations of the armor. Given these levels' lack of standardized criteria, validating manufacturers' claims through verified test results is crucial.

NIJ Standard 0101.06 also outlines rigorous testing conditions to ensure the armor performs effectively in various environmental conditions. These include temperature, moisture, and mechanical wear tests to simulate the real-world conditions that body armor might be subjected to during its lifespan. This approach ensures that the armor meets the ballistic resistance requirements when new and maintains its protective capabilities throughout its intended use period. NIJ Standard 0101.07 was released in November 2023 and will soon replace NIJ Standard 0101.06

NIJ Standard 0101.07 Overview (United States)

The National Institute of Justice (NIJ) in the United States has officially published the NIJ Standard 0101.07, marking a significant advancement in body armor performance standards. This update aligns with the latest developments in body armor technology and evolving threat landscapes in law enforcement.

Critical Developments in NIJ Standard 0101.07

Enhanced Testing for Female Body Armor: This standard introduces specialized testing for body armor tailored to female law enforcement officers, focusing on fit and protection.

Updated Ballistic Protection Levels: Reflecting the evolving nature of threats, the standard revises protection levels for both handgun and rifle threats.

Revised Protection Levels

Handgun Threats (NIJ HG1 and HG2):

NIJ HG1: Previously known as Level II, it's designed for protection against 9mm Luger FMJ RN bullets and .357 Mag JSP rounds.

NIJ HG2: Previously known as Level IIIA, it offers enhanced protection, including against threats like .44 Mag JHP and 9mm Luger FMJ RN bullets.

Rifle Threats (NIJ RF1, RF2, and RF3):

NIJ RF1: An upgrade from the former Level III, protecting against threats such as the 7.62x51mm M80 Ball NATO FMJ and 5.56mm M193 BT.

NIJ RF2: Includes protection against 5.56mm M855 BT, in addition to the threats covered under RF1.

NIJ RF3: The highest level under this standard, equivalent to the previous Level IV, is designed to stop armor-piercing rounds like the .30-06 M2 AP.

Integration with ASTM Standards:

The 0101.07 standard incorporates various ASTM standards, harmonizing testing methods and practices to enhance consistency and reliability in body armor testing.

Anticipated Impact

This update is expected to bolster law enforcement agencies' confidence in the effectiveness of body armor against contemporary threats, particularly with the inclusion of advanced rifle threat levels.

The standard's comprehensive approach, including focusing on female-specific body armor, demonstrates NIJ's commitment to officer safety and operational preparedness.

NIJ Standard 0101.07 represents a pivotal evolution in body armor standards. It addresses the dynamic and complex nature of threats encountered by law enforcement officers, reaffirming NIJ's dedication to improving officer safety through stringent testing and body armor certification, thereby ensuring optimal protection in various operational environments.

NIJ Standard 0123.00 Overview (United States)

The NIJ Standard 0123.00, a newly established set of guidelines by the National Institute of Justice (NIJ) in the United States, outlines specifications for NIJ Ballistic Protection Levels and their associated test threats. This standard plays a crucial role in the certification and performance evaluation of body armor, ensuring it meets the demands of modern law enforcement operations.

Key Features of NIJ Standard 0123.00

Detailed Ballistic Protection Levels: The standard provides a structured classification of body armor levels, each designed to protect against specific ballistic threats. This approach ensures that law enforcement and military personnel receive armor suited to their operational requirements.

Comprehensive Threat Coverage: It encompasses a wide range of ballistic threats, from handgun to high-caliber rifle ammunition, aligning with the diverse scenarios faced by officers in the field.

Stringent Testing Protocols: The standard specifies rigorous testing methods, ensuring that body armor meets the baseline protection requirements and maintains its protective capabilities in various environmental conditions and through wear and tear.

Impact and Significance

Enhanced Officer Safety: By specifying distinct protection levels and corresponding threats, the standard aims to improve the safety of law enforcement personnel significantly.

Guidance for Body Armor Manufacturers: It serves as a critical reference for manufacturers, guiding the design and production of body armor to meet precise protection criteria.

Confidence in Body Armor Effectiveness: The detailed classifications and rigorous testing methods instill confidence in law enforcement agencies regarding the reliability and effectiveness of body armor in different operational settings.

NIJ Standard 0123.00 marks a significant advancement in body armor standards. It provides a comprehensive and detailed framework for understanding and evaluating ballistic protection levels tailored to the evolving needs of law enforcement and military personnel. This standard is a testament to NIJ's commitment to enhancing the safety and preparedness of officers, ensuring they are well-equipped to face various threats in their line of duty.

Ballistic Standards by ASTM International

The American Society for Testing and Materials (ASTM) is pivotal in setting global benchmarks for ballistic-resistant protective materials. Through its comprehensive standards, ASTM provides essential guidelines for the performance, testing, and classification of materials used in body armor, which is critical for both the U.S. and international markets. These standards ensure consistency in the quality and performance of ballistic protection equipment, adapting to evolving threats and technological advancements.

The American Society for Testing and Materials (ASTM International) plays a crucial role in establishing global standards for materials that offer ballistic resistance. These standards are vital for ensuring the safety and effectiveness of body armor and similar protective gear, catering to the needs of both the U.S. and international markets. By providing detailed guidelines on performance, testing, and classification, ASTM International helps maintain uniformity in the quality and functionality of ballistic protection products. This is especially important as threats evolve and new technologies emerge.

Extensive Overview of ASTM International Ballistic Standards

ASTM International's comprehensive suite of ballistic standards encompasses a broad range of tests and classifications related to body armor:

ASTM E3004-22: Focuses on the preparation and verification of clay blocks for testing the ballistic resistance of torso body armor.

ASTM E3017-17a: Describes the methodology for assessing the penetration resistance and backface deformation of ballistic-resistant torso armor and shoot packs.

ASTM E3110/E3110M-22: Outlines the procedure for collecting ballistic limit data for torso body armor and shoot packs.

ASTM E3112-17: Provides the standard test method for ballistic-resistant products, including shoot packs.

ASTM E29-13: Establishes guidelines for using significant digits in test data to ascertain compliance with specifications.

ASTM E3005-20: Updates terminology for body armor, ensuring clarity in technical standards.

ASTM E3368/E3368M-23: Sets the specifications for ballistic-resistant helmets worn by U.S. public safety officers.

ASTM E3347/E3347M-22: Details the specifications for ballistic-resistant shields used by law enforcement officers.

ASTM E3111/E3111M-22: Standardizes test methods for ballistic-resistant head protection.

ASTM D5264-98 219: Addresses the abrasion resistance of printed materials through the Sutherland Rub Tester method.

ASTM E3192-2: Provides a standard practice for conditioning soft armor by tumbling.

Objectives Behind the Standards

Each standard from ASTM International targets specific facets of ballistic resistance and protective gear:

Enhancing the accuracy and reliability of test methods for evaluating ballistic resistance.

Establishing a clear and comprehensive vocabulary for discussing body armor, ensuring industry-wide understanding.

Focusing on both the blunt trauma protection offered by armor and its resistance to penetration.

Evaluating the effectiveness of ballistic-resistant headgear, shields, and other protective products in law enforcement and public safety contexts.

Setting forth performance requirements and classification systems that reflect current threats and technological capabilities.

ASTM International's ballistic standards are fundamental to the development, testing, and certification of body armor and related protective gear. They offer a solid framework that aligns with the latest in threat landscapes and technological innovations, guaranteeing that protective equipment adheres to the highest standards of safety and performance. This extensive collection of standards serves as an essential resource for manufacturers, certification entities, and users involved in the field of ballistic protection.

VPAM Armor Standard (Europe)

The VPAM (Vereinigung der Prüfstellen für angriffshemmende Materialien und Konstruktionen) standards, highly regarded in Europe, offer detailed guidelines for personal body armor across various levels. These standards effectively respond to diverse ballistic threats, catering to the specific needs of European law enforcement, military, and civilian security sectors.

Comprehensive Listing of VPAM Standards

VPAM's standards cover a broad range of applications, including body armor, helmets, and vehicle protection:

VPAM APR 2006: Standards for bullet-resistant helmets.

VPAM KDIW 2004: Specifications for vehicle armor.

VPAM BSW 2006: Criteria for ballistic body armor.

VPAM HVN 2009: Guidelines for ballistic protection in civilian vehicles.

VPAM PM Formerly VPAM PM 2007: General standards for ballistic materials and test methods.

Detailed Overview of VPAM PM Levels

The VPAM PM (Prüfverfahren Materialien) scale, updated in 2009, categorizes body armor into levels PM1 to PM14, with each level designed to protect against specific threats:

PM 1: Suitable for .22 Long Rifle Lead Round-Nose bullets, tested at a velocity of 360±10 m/s.

PM 2: Protects against 9×19mm Parabellum Full Metal Jacket Round-Nose bullets at 360±10 m/s.

PM 3: Provides protection against 9×19mm Parabellum Full Metal Jacket Round-Nose bullets at 415±10 m/s.

PM 4: Designed to stop .357 Magnum Jacketed Soft Point bullets at 430±10 m/s and .44 Magnum Jacketed Hollow Point bullets at 440±10 m/s.

PM 5: For .357 Magnum Full Metal Jacket bullets at a velocity of 580±10 m/s.

PM 6: Protects against 7.62×39mm Mild Steel Core bullets at 720±10 m/s.

PM 7: Covers 5.56×45mm SS109 bullets at 950±10 m/s and 7.62×51mm Full Metal Jacket bullets at 830±10 m/s.

PM 8: Designed for 7.62×39mm API BZ bullets at 740±10 m/s.

PM 9: Protects against 7.62×51mm Armor-Piercing bullets at 820±10 m/s.

PM 10: Suitable for 7.62×54mmR API bullets at 860±10 m/s.

PM 11: Intended for 7.62×51mm AP bullets at 930±10 m/s.

PM 12: Protects against 7.62×51mm Swiss P AP bullets at 810±10 m/s.

PM 13: Designed for 12.7×99mm (.50 cal) bullets at 930±10 m/s.

PM 14: Protects against 14.5×114mm API bullets at 911±10 m/s.

Purpose and Application

VPAM standards are designed to provide comprehensive protection against various ballistic threats. These levels ensure that personnel are equipped with armor capable of withstanding specific threats prevalent in their operational environments. The standards are crucial for armor manufacturers, security planners, and users, offering guidance on selecting appropriate protection levels based on anticipated threat scenarios.

The VPAM standards, with their detailed classification of protection levels and specific ballistic threats, play a vital role in enhancing the safety and readiness of law enforcement, military, and civilian personnel in Europe. They provide a clear framework for developing, testing, and certifying personal protective equipment, ensuring that it meets the highest standards of safety and effectiveness against varied ballistic threats.

TR Armor Standard (Germany)

The Technische Richtlinie (TR) Ballistische Schutzwesten is a comprehensive standard predominantly utilized in Germany, providing detailed guidelines for body armor used in law enforcement, military, and civilian sectors. This standard, known for its rigorous requirements, ensures that body armor meets stringent protection and quality criteria. The TR standard is vital for ensuring the safety and effectiveness of body armor used within Germany and for international export.

Detailed Overview of TR Schutzklassen (SK) Levels

The TR standard categorizes body armor into different Schutzklassen (SK) levels, each addressing specific ballistic threats:

SK L: This level is primarily designed to protect against lower-threat handguns such as 9×19mm Parabellum. The armor is tested against 9×19mm FMJ round-nose lead-core bullets at a velocity of 360±10 m/s, including point-blank shots.

SK 1: This level also targets 9×19mm Parabellum threats but includes additional police special rounds. The armor is tested against:

9×19mm FMJ round-nose lead-core bullets at a velocity of 415±10 m/s.

9×19mm QD-PEP II/S police special round bullets at 460±10 m/s.

9×19mm Action 4 police special round bullets at 460±10 m/s.

SK 2 (PM 5): Designed to protect against .357 Magnum threats, this level tests the armor's resistance to .357 Magnum FMJs (brass at the nose) bullets at a velocity of 580±10 m/s.

SK 3 (PM 7): Aimed at rifle threats, this level includes protection against:

5.56×45mm SS109/M855 FMJ bullets at 950±10 m/s.

7.62×51mm DM111 steel-core bullets at 830±10 m/s.

SK 4 (PM 9): The highest standard class under the TR, intended for high-caliber and armor-piercing threats such as 7.62×51mm P80 armor-piercing bullets, tested at a velocity of 820±10 m/s.

Purpose and Application

The TR standard's protection classes (SK L to SK 4) are designed to offer comprehensive coverage against various ballistic threats, from handguns to high-powered rifle ammunition. This wide-ranging protection is crucial for law enforcement and military personnel facing different threat levels in various operational scenarios.

The TR ballistic protection standard is a testament to Germany's commitment to ensuring the highest level of safety for its law enforcement, military, and civilian personnel. By offering a detailed classification of protection levels against specific threats, the TR standard plays a vital role in guiding the development and testing of body armor. It ensures that the armor meets the immediate protection needs and aligns with the evolving nature of ballistic threats, thereby maintaining a high standard of safety and reliability in protective gear.

HOSDB/CAST Armor Standard (United Kingdom)

The Home Office Scientific Development Branch (HOSDB), now called the Home Office Centre for Applied Science and Technology (CAST), sets forth the standards for police body armor in the United Kingdom. These standards have been developed to address the specific threats encountered by UK law enforcement, with a strong emphasis on rigorous testing for knife, spikes, and ballistic resistance, primarily focused on torso protection.

Evolution of HOSDB Standards

1993: Introduction of the first standard addressing knife threats; expanded in 1995 to include ballistic threats.

1999: Major revisions introducing the guided-mass knife drop test, non-edged spike testing, and tiered protection levels.

2003: Introduction of the HG1/A ballistic protection level with an increased permissible back-face signature (BFS).

2007: Major update with increased protection levels for more powerful handgun and rifle threats, in-production quality testing, and additional compliance tests.

2017: The latest iteration supersedes all previous standards, focusing on current operational threats and end-user needs.

2017 Home Office Body Armor Standard

This standard specifies the minimum testing requirements for stab and bulletproof vests, significantly focusing on contemporary threats. Key features of the 2017 standard include:

Bulletproof Vests Requirement: All stab and bulletproof inserts must be 100% waterproof, as stipulated by ISO 811:1981, and regularly tested for compliance.

Enhanced Testing Requirements: Including various levels of ballistic protection, periodic in-life monitoring, production quality testing, formed armor testing for molded or female-specific vests, and rifle test requirements for both male and female torso protection.

Types of Body Armor: Categorization of stab and bulletproof inserts, distinguishing between flat (unformed) armor for men and shaped (formed) armor for women.

Separate Testing for Flat and shaped Armor: Ensuring body armor is tested according to its intended use and the user's body shape.

Detailed Protection Levels: Clearly defined protection levels, specifying the type of ammunition, bullet mass, test range, BFS limits, and velocity requirements.

Protection Levels

HO1 Protection Level

Classification: 9 mm FMJ

Test Rounds:

MEN 9 mm FMJ DM11A1B2, 8.0 g (124 grain), Velocity: 365 ± 10 m/s

Federal Premium 9 mm JHP P9HST1, 8.0 g (124 grain), Velocity: 365 ± 10 m/s

Backface Signature (BFS): Max mean 44.0 mm

HO2 Protection Level

Classification: 9mm FMJ

Test Rounds:

MEN 9 mm FMJ DM11A1B2, 8.0 g (124 grain), Velocity: 430 ± 10 m/s

Federal Premium 9 mm JHP P9HST1, 8.0 g (124 grain), Velocity: 430 ± 10 m/s

BFS: Max mean 44.0 mm

HO3 Protection Level

Classification: Rifle 7.62 calibre

Test Rounds:

Radway Green 7.62 mm NATO Ball L44A1/L2A2, 9.3 g (144 grain), Velocity: 830 ± 15 m/s

7.62 × 39 mm surrogate, 7.9 g (122 grain), Velocity: 705 ± 15 m/s

BFS: Max mean 25.0 mm, Single shot limit 30.0 mm

HO4 Protection Level

Classification: Rifle 7.62 calibre

Test Rounds:

SAKO .308 Win 480A Powerhead or Barnes .308 TSX BT, 10.7 g (165 grain), Velocity: 820 ± 15 m/s

BFS: Max mean 25.0 mm, Single shot limit 30.0 mm

Note: Armor tested to HO4 must also meet HO3 requirements.

SG1 Protection Level

Classification: Shotgun 12-gauge True Cylinder

Test Rounds: Winchester 1 oz. Rifled 12RSE, 28.4 g, Velocity: 435 ± 25 m/s

BFS: Max mean 25.0 mm, Single shot limit 30.0 mm

Special Protection Levels

0.357” Magnum Soft Point Flat Nose Remington R357M3, 10.2 g, Velocity: 390 ± 10 m/s, 455 ± 10 m/s

5.56 × 45 mm SS109/Ball L17A1/L15A1, 4.01 g (62 grain), Velocity: 920 ± 15 m/s

Carbine 5.56 × 45 mm NATO Federal Tactical Bonded 5.56 mm (.223) LE223T3, 4.01 g (62 grain), Velocity: 750 ± 15 m/s

BFS for Special Rounds: Max mean 25.0 mm, Single shot limit 30.0 mm

Key Features of HOSDB 2017 Standard

Waterproof Requirement: All armor inserts must be 100% waterproof (ISO811: 1981).

Periodic In-Life Monitoring (ILM): Ensures consistent protection throughout the armor's lifespan.

Production Quality Testing (PQT): Ensures high-quality production of soft body armor.

Formed Armor Testing: Mandatory for molded or female-specific armor.

Rifle Test for Torso Protection: Both male and female torso armor must undergo rifle testing.

Separate Tests for Flat and shaped Armor: Ensuring accurate assessment of protection level.

Special Testing Methods: Separate testing for men’s and women’s body armor.

Purpose and Application

The HOSDB/CAST standards are crucial for ensuring that UK police officers are equipped with body armor that meets the unique ballistic and edged weapon threats prevalent in the UK. The standards focus on reducing the risk of internal injuries from blunt force trauma and ensure that body armor adheres to high safety and performance standards throughout its lifespan. This comprehensive approach underscores the UK's dedication to the safety and effectiveness of protective gear for law enforcement personnel, ensuring their preparedness in various operational scenarios.

UL Ballistic Standards (United States)

Underwriters Laboratories (UL) is a globally recognized organization that develops standards and test procedures for products, materials, and systems, including ballistic-resistant protective materials. UL standards are especially significant in the U.S. and play a crucial role internationally. They provide stringent guidelines for the performance, testing, and certification of materials used in ballistic resistance, particularly for building products like doors, windows, and wall panels.

The UL 752 standards for bullet-resisting equipment include

UL 752 Standard for Bullet-Resisting Equipment: Encompasses overall guidelines and testing methodologies for bullet-resisting materials.

UL 752-1 General Requirements: Covers fundamental requirements for materials, construction, and testing of bullet-resisting equipment.

Specific Levels and Threats Addressed in UL 752

Level 1: Designed to stop three shots of a 9mm Luger 124 grain FMJ lead core handgun ammunition at a velocity of 1175 to 1293 fps.

Level 2: Tailored to resist three shots of a .357 Magnum 158 grain lead soft point handgun ammunition at 1250 to 1375 fps.

Level 3: Capable of stopping three shots of a .44 Magnum 240 grain lead semi-wadcutter gas-checked handgun ammunition at a velocity of 1350 to 1485 fps.

Level 4: Designed to withstand one shot of a .30 caliber rifle lead core soft point (.30-06 caliber) ammunition at a velocity of 2540 to 2794 fps.

Level 5: Can resist one shot of a 7.62mm rifle lead core full metal copper jacket, military ball (.308 caliber) ammunition at a velocity of 2750 to 3025 fps.

Level 6: Tailored to stop five shots of a 9mm Luger 124 grain FMJ lead core handgun ammunition at a velocity of 1400 to 1540 fps.

Level 7: Designed for protection against five shots of a 5.56mm rifle full metal copper jacket with lead core (.223 caliber) ammunition at a velocity of 3080 to 3383 fps.

Level 8: Can resist five shots of a 7.62mm rifle lead core full metal copper jacket, military ball (.308 caliber) ammunition at a velocity of 2750 to 3025 fps.

Level 9: Intended to stop one shot of a .30 caliber rifle lead core soft point (.30-06 caliber) ammunition at a velocity of 2540 to 2794 fps.

Level 10: Can resist one shot of a 7.62mm rifle armor piercing (AP) (.308 caliber) ammunition at a velocity of 2657 to 2900 fps.

Level 11: Tailored to withstand one shot of an 8.0mm rifle lead core full metal copper jacket, military ball (.30-06 caliber) ammunition at a velocity of 2540 to 2794 fps.

Level 12: Designed for protection against one shot of a 12.7mm (.50 caliber) armor-piercing ammunition at a velocity of 2810 to 3080 fps.

The Significance of UL 752 Ballistic Standards

The UL 752 ballistic standards serve as a crucial benchmark in safety and security, offering a meticulously detailed framework for evaluating the ballistic resistance of diverse materials and products. These standards are meticulously crafted, specifying the types of ammunition the equipment can resist and detailing the construction and materials employed. This encompasses a variety of materials, including different compositions and thicknesses of glass, polycarbonate, steel, and other composites, each engineered to meet the rigorous requirements of their respective threat levels.

The UL 752 standards ensure that bullet-resisting equipment adheres to the highest safety and security standards by clearly delineating specific threat levels and their associated protective capabilities. This is particularly vital in environments where ballistic threats pose a significant concern, ranging from civilian to law enforcement contexts.

UL ballistic standards are foundational to the global safety and security infrastructure. They guide manufacturers, architects, and security professionals in developing and selecting bullet-resisting materials and products, ensuring reliable protection against a broad spectrum of ballistic threats. These standards underscore the importance of rigorous testing procedures and classification systems and reinforce the commitment to safeguarding lives in varied and potentially hazardous environments.

MIL-STD (United States Military Standards)

The MIL-STD standards, developed by the United States Department of Defense, represent a critical set of guidelines and specifications for military equipment, including body armor. These standards are integral to the United States military's operational readiness, ensuring that all equipment, particularly body armor, meets the stringent requirements necessary for the rigors of military service.

Key Features of MIL-STD for Body Armor

Specific Requirements: MIL-STD sets detailed requirements for the design, materials, and construction of military body armor, ensuring it can withstand varied and extreme conditions encountered in military operations.

Rigorous Ballistic Testing: These standards include stringent ballistic testing procedures that often exceed the rigor found in civilian body armor standards. The testing protocols are designed to simulate a wide range of combat scenarios, ensuring that body armor offers maximum protection against various ballistic threats, including high-caliber and armor-piercing ammunition.

Environmental and Durability Testing: MIL-STD also mandates environmental testing, ensuring body armor maintains its protective qualities in diverse climates, ranging from extreme cold to desert heat. Durability testing under these conditions is crucial, as the gear must withstand not only ballistic threats but also the wear and tear of harsh environments.

Classification and Protection Levels

Levels of Protection: While specific classification details might be classified, MIL-STD body armor is known to be rated for higher threat environments than most civilian standards. This includes protection against advanced ballistic threats and improvised explosive devices (IEDs).

Specialized Armor Types: MIL-STD covers a range of body armor types, from standard infantry vests to specialized armor for pilots, naval personnel, and other specific roles. Each type is tailored to the unique requirements of its intended use, providing the necessary mobility, protection, and functionality.

MIL-STD (United States Military Standards) for Body Armor

MIL-STD standards, developed by the United States Department of Defense, specify rigorous requirements for military body armor. These standards are integral to ensuring military personnel's safety and operational effectiveness.

Key MIL-STD Specifications for Body Armor

MIL-STD-662F: V50 Ballistic Test for Armor

Purpose: Determines the velocity at which a bullet will penetrate armor 50% of the time (V50).

Application: Used to test helmets, vests, and other ballistic protection gear.

Materials Tested: Kevlar, Dyneema, ceramics, and composite materials.

MIL-DTL-32332 (MR): Armor Plate, Steel, Wrought, Ultra-High-Hardness

Purpose: Specifies ultra-high-hard steel armor plates for maximum ballistic protection.

Application: Used for vehicle armor, protective inserts, and structural armor applications.

Threat Level: Resistant to high-velocity small arms and artillery shell fragments.

MIL-DTL-46100E: Armor Plate, Steel, Wrought, High-Hardness

Purpose: Covers high-hardness armor (HHA) used in ballistic protection.

Application: For armored vehicles and body armor plates.

Threat Level: Designed to protect against high-velocity bullets and fragmentation.

MIL-STD-810G: Environmental Engineering Considerations and Laboratory Tests

Purpose: Provides guidelines for environmental durability testing of military equipment, including body armor.

Application: Ensures armor performance under extreme environmental conditions like temperature, humidity, and salt fog.

MIL-DTL-44050B: Cloth, Laminated, Ballistic, Aramid

Purpose: Specifies the requirements for Kevlar fabric used in body armor.

Application: For soft body armor vests, protective panels, and clothing.

Materials: Focused on aramid (Kevlar) fabric with specific weave and density requirements.

Impact on Body Armor Development

Innovation Driver: MIL-STD standards push for continuous improvement in body armor materials and design, fostering advancements in lighter and more protective materials.

Global Influence: Though specific to the U.S. military, these standards often influence international body armor designs and testing protocols.

Applications and Impact

Military Operations: MIL-STD body armor is designed for use across various military branches, including the Army, Navy, Air Force, Marines, and Coast Guard. It provides soldiers with the necessary protection in combat and peacekeeping missions.

Research and Development Influence: The standards set by MIL-STD often drive innovation in body armor technology. The demand for lighter, more flexible, and more protective materials has led to significant advancements in personal protection.

The MIL-STD for body armor underscores the United States military's commitment to the safety and effectiveness of its personnel. Its rigorous requirements and comprehensive testing procedures ensure that military body armor offers superior protection, durability, and functionality, crucial for military service's diverse and challenging demands.

MIL-STD standards for body armor are crucial in setting the benchmark for military-grade protection. They ensure that personnel have the most advanced protective gear capable of withstanding various ballistic threats and harsh environmental conditions. The U.S. military maximizes soldier protection and operational effectiveness by continuously evolving these standards.

This overview provides a glimpse into the MIL-STD standards relevant to body armor, reflecting their complexity and pivotal role in defining military-grade ballistic protection. The detailed specifications and threat levels for many of these standards are often restricted due to security considerations.

GOST Armor Standard (Russia)

The GOST R 50744-95 standard is pivotal for body armor in the Russian Federation. With significant revisions in 2017, it addresses a broad spectrum of evolving ballistic threats. This standard is comprehensive and diverse, covering various protection classes to meet the specific security needs of Russian law enforcement and military personnel. It reflects Russia's strategic approach to adapting armor technology to counter conventional and emerging threats.

Comprehensive Listing of GOST Standards

The GOST armor standard provides a detailed classification of protection levels, both before and after its 2017 revision:

Pre-2017 GOST Standards: Class 1 to Class 6A

Post-2017 Revised GOST Standards: Classes BR1 to BR6

Detailed Overview of GOST Protection Levels

The GOST classes are specifically designed to protect against a wide range of ballistic threats:

Class 1 (Pre-2017): Targets protection against low-caliber handguns like the 9×18mm Makarov and 7.62×38mmR Nagant, common in the Russian law enforcement arsenal.

Class 2 and 2A (Pre-2017): Designed for higher velocity handguns and specific shotgun threats, enhancing the protection level for officers in more dangerous environments.

Class 3 (Pre-2017): Offers protection against standard rifle threats, including common military calibers used in the region.

Class 4 to 6A (Pre-2017): These classes cover a broad range of rifle ammunition, including armor-piercing (AP) and incendiary rounds, reflecting the need for higher protection in combat and high-threat environments.

BR1 to BR6 (Post-2017): The revised classes significantly expand the scope of protection, with BR1 addressing primary rifle threats and BR6 capable of withstanding high-caliber threats like the 12.7×108mm API. This broad range indicates Russia's focus on comprehensive protection against traditional and advanced ballistic threats.

BR1: Designed for protection against low-caliber handguns. Typically, this class tests armor against rounds like the 9×18mm Makarov, common in personal defense weapons in Russia.

BR2: Tailored to slightly higher caliber and velocity handguns, providing enhanced protection in urban law enforcement scenarios.

BR3: Steps to address threats from more powerful handguns, including semi-automatic pistols used in criminal activities.

BR4: Marks the transition to rifle protection, focusing on standard rifles used in both criminal elements and potential terrorist activities.

BR5: Offers protection against more powerful rifle ammunition, including some types of military-grade rifles that might be encountered in high-threat environments or combat zones.

BR6: The highest level in this standard, BR6 is designed to withstand shots from high-caliber and armor-piercing ammunition, like the 12.7×108mm API. This level is essential for personnel in war zones or areas with heightened military threats.

Purpose and Application

The GOST armor standards, particularly the post-2017 revision, are fundamental to ensuring that Russian military and law enforcement personnel are equipped with body armor that provides robust protection across a spectrum of security scenarios. These standards encompass a range of protection classes, from BR1 to BR6, each meticulously developed to address specific ballistic threats. The standards are a testament to Russia's commitment to maintaining high safety and protection standards for its forces.

BR1 to BR6 Standards: These classes cover various potential ballistic threats, ranging from lower-caliber handguns to high-caliber, armor-piercing rounds. This reflects the diverse and potentially high-risk scenarios that Russian forces may encounter.

Rigorous Testing and Classification: The standards undergo rigorous testing to ensure each class meets the required protection level against designated threats, including advanced armor-piercing and incendiary rounds.

Impact on Russian Defense and Law Enforcement: The GOST standards play a critical role in the Russian defense landscape by providing a structured and detailed classification of ballistic protection levels. They ensure that defense and law enforcement personnel are adequately equipped to face various ballistic threats.

Adaptation to Evolving Threats: The comprehensive approach to body armor classification underlines Russia's dedication to effectively adapting its armor technology to counter existing and emerging threats in various operational settings.

The GOST armor standards are integral to Russia's national security framework, ensuring its military and law enforcement personnel access the most effective ballistic protection. The standards focus on a broad spectrum of threats, and their rigorous testing protocols underscore the country’s commitment to the safety and preparedness of its security forces in an ever-evolving global security environment.

Detailed Breakdown of GA141 Armor Standard (China)

The GA141 standard, as upheld by China's Ministry of Public Security, plays a vital role in defining the protective capabilities of police armor against ballistic threats specific to China. Revised in 2010, this standard provides a comprehensive framework for categorizing armor based on its ability to withstand various threats, from handguns to high-powered rifles.

Comprehensive Listing of GA141 Standards

GA141-2010: This latest version of the standard details the protection levels tailored to the unique ballistic threats encountered in China.

Levels of Protection and Specific Threats

GA 1: Designed for protection against low-velocity handgun threats, specifically the 7.62×17mm rounds typically fired from type 64 or type 77 pistols.

GA 2: Tailored to counter 7.62×25mm Tokarev rounds, a common threat from type 54 pistols, representing higher velocity handgun threats.

GA 3: Enhances protection against the same 7.62×25mm Tokarev rounds but fired from a type 79 submachine gun, indicating the armor’s capability to withstand higher velocity impacts.

GA 4: Focuses on 7.62×25mm Tokarev Armor Piercing (AP) rounds, again from type 79 submachine guns, reflecting the need for higher-level protection against more penetrating threats.

GA 5: Addresses the need to protect against rifle threats, specifically designed to stop 7.62×39mm steel-core bullets commonly used in type 56 or type 81 assault rifles.

GA 6: The highest protection level under this standard, capable of withstanding 7.62×54mmR steel-core bullets, a threat typically associated with sniper rifles such as type 79 or type 85.

Application and Purpose

Each level within the GA141 standard demonstrates China's proactive approach to adapting its body armor capabilities to meet its region's evolving and specific ballistic threats. This standard is a testament to China’s commitment to providing law enforcement personnel with armor that offers adequate protection, considering both the nature of domestic threats and the operational requirements of its security forces.

The GA141 armor standard is integral to China’s national security framework. By offering a detailed and structured classification of ballistic protection levels, the GA141 standard ensures that Chinese law enforcement is equipped with body armor that meets stringent safety and performance criteria. This comprehensive approach to body armor classification underlines China’s dedication to maintaining high safety standards and ensuring the well-being of its security personnel in various operational settings.

Honorable Mentions

This comprehensive overview of global ballistic standards beyond the well-known ones like NIJ and VPAM provides a deeper insight into the diverse approaches to ballistic protection worldwide. Each standard caters to specific regional requirements, ensuring the safety and effectiveness of body armor in various contexts.

FBI Ballistic Protocol

Focus on Real-World Threats: Specifically designed to test body armor against threats most commonly encountered by FBI agents, including high-velocity rounds and unique threat projectiles.

Operational Practicality: Balances the need for high-level ballistic protection with the practicality of wearability in field operations, ensuring agents can perform their duties effectively while adequately protected.

DEA Ballistic Protocol

Rigorous Testing for Special Threats: Emphasizes protection against particular ammunition types used in criminal activities, ensuring DEA agents are well-protected against specific threats encountered during drug enforcement operations.

Adaptation to Evolving Drug Enforcement Scenarios: Regularly updated to reflect the changing nature of threats in drug enforcement, providing agents with armor that meets the latest safety and performance requirements.

ISO (International Organization for Standardization) Standards

ISO 14876 (Body Armor): These standards provide general requirements, classification, and performance guidelines for body armor. They are designed to ensure consistency and reliability in ballistic protection globally, setting a baseline for quality and safety in personal protective equipment.

DIN Standards (Germany)

Institution: Managed by the Deutsches Institut für Normung, the German national standardization body.

Usage: German DIN standards for ballistic protection are sometimes used with other European standards, reflecting a comprehensive approach to personal protective equipment in various threat environments.

Stanag 2920 (NATO Standardization Agreement)

Purpose: A NATO standard for testing ballistic protection materials and combat helmets.

Relevance: Widely used in military specifications, it provides a common framework for NATO members to evaluate and standardize military protective gear.

Australian and New Zealand Standards (AS/NZS)

Example: AS/NZS 2343 for bullet-resistant panels and elements.

Scope: These standards cover the testing and classification of ballistic resistance in Australia and New Zealand, ensuring regional relevance and applicability.

Canadian Standards (CGSB)

Specific Standard: CGSB standard 45.1 for ballistic-resistant police body armor.

Application: Developed by the Canadian General Standards Board, these standards are vital for the safety of Canadian law enforcement and military personnel, aligning with Canada's unique security landscape.

Brazilian Standard (NBR)

Key Standard: NBR 15000 by Associação Brasileira de Normas Técnicas.

Focus: Addresses ballistic vests for military and law enforcement use in Brazil, ensuring protective gear is suited to the country's specific threats and operational conditions.

Bureau of Indian Standards (BIS)

Notable Standard: IS 17051 for body protectors.

Role: Set by the Bureau of Indian Standards, these standards define the requirements for body armor used by Indian law enforcement and military, catering to the distinct security needs of India.

Japanese Standards (JIS)

Coverage: Include specifications for body armor focusing on materials and construction methods.

Target Audience: Primarily tailored for Japan’s law enforcement agencies, reflecting the country's specific public safety and security requirements.

South Korean Standards (KS)

Managed By: Korean Agency for Technology and Standards (KATS).

Purpose: Establish standards for ballistic protection in South Korea, ensuring that body armor meets the country's specific safety and performance criteria in security contexts.

Each of these standards plays a crucial role in its respective region, ensuring that body armor and protective gear meet specific local needs and threats while contributing to the global understanding of ballistic protection and safety.

As we conclude our in-depth exploration of global ballistic standards, it's evident that these guidelines are more than just technical specifications. They are dynamic, evolving systems that reflect a commitment to the safety and security of those on the front lines - law enforcement, military operations, or civilian protection. These standards, from the NIJ in the United States to VPAM in Europe and beyond, not only provide a framework for assessing and ensuring the effectiveness of body armor but also symbolize a global commitment to adapting to the ever-changing landscape of ballistic threats.

In a world where security threats constantly evolve, staying informed and updated with these standards is crucial for manufacturers, policymakers, and end-users. This comprehensive understanding helps make informed decisions that align with specific security needs and threats.

At IntelAlytic, we understand these standards' significance in the broader market and competitor analysis context in operations, compliance, training, analytics, and risk management, particularly within the specialized world of body armor. Our team, with over fifty years of combined industry expertise, is dedicated to providing profound insights and educational resources to navigate these complex landscapes.

For those seeking support in market analysis, competitor intelligence, or any aspect of operations and compliance related to body armor and public safety markets, IntelAlytic is your go-to partner. We are equipped to offer comprehensive support, from analytics and risk management to training and operational guidance.

Contact IntelAlytic today for all your market and competitor analysis needs in the dynamic world of body armor and beyond. Let us help you stay ahead in an ever-evolving security landscape. Know More. Risk Less.

Learn More About IntelAlytic

Explore our Services

The Armor List: The world’s largest database of body armor, materials, and companies. No fluff, just facts to power your decisions.

Resources and Reference Guides

NIJ Standards

NIJ Standard-0101.06: Ballistic Resistance of Body Armor 2008

NIJ Standard-0101.07: Ballistic Resistance of Body Armor 2023

NIJ Standard-0123.00: Specification for Ballistic Protection Levels 2023

NIJ Standard 0115.00: Stab, Knife, and Spike Resistance of Body Armor 2000

NIJ Standard 0104.02: Riot Helmets and Face Shields for Riot Control 1984

NIJ Standard 0108.01: Ballistic Protective Materials for Body Armor 1985

NIJ Standard 0106.01: Ballistic Helmets for Law Enforcement Officers 1981

NIJ Standard 0117.00: Public Safety Bomb Suit Standard 2016

ASTM Standards

ASTM E3004-22: Standard Specification for Preparation and Verification of Clay Blocks Used in Ballistic-Resistance Testing of Torso Body Armor

ASTM E3017-17a: Standard Test Method For Resistance To Penetration And Backface Deformation For Ballistic-Resistant Torso Body Armor And Shoot Packs

ASTM E3110/E3110M-22: Standard Test Method for Collection of Ballistic Limit Data for Ballistic-resistant Torso Body Armor and Shoot Packs

ASTM E3112-17: Standard Test Method for Ballistic-resistant Products and Shoot Packs

ASTM E29-13: Standard Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

ASTM E3005-20: Standard Terminology for Body Armor

ASTM E3368/E3368M-23: Standard Specification for Ballistic-Resistant Helmets Worn by U.S. Public Safety Officers

ASTM E3347/E3347M-22: Standard Specification for Ballistic-Resistant Shields Used by Law Enforcement Officers

ASTM E3111/E3111M-22: Standard Test Methods for Ballistic Resistant Head Protection

ASTM D5264-98 219: Standard Practice for Abrasion Resistance of Printed Materials by the Sutherland Rub Tester

ASTM E3192-2: Standard Practice for Soft Armor Conditioning by Tumbling

U.S. Military Standards:

MIL-STD-662F MILITARY STANDARD: V50 BALLISTIC TEST FOR ARMOR (18 DEC 1997)

MIL-DTL-32332, DETAIL SPECIFICATION: ARMOR PLATE, STEEL, WROUGHT, ULTRA-HIGH-HARDNESS (24-JUL-2009)

MIL-DTL-46100E, DETAIL SPECIFICATION: ARMOR PLATE, STEEL, WROUGHT, HIGH-HARDNESS (08 JUL 2008) [SUPERSEDING MIL-A-46100D]

MIL-STD-810G 31: ENVIRONMENTAL ENGINEERING CONSIDERATIONS AND LABORATORY TESTS (1 January 2000 ) [SUPERSEDING MIL-STD-810F]

MIL-DTL-44050B, DETAILED SPECIFICATION: CLOTH, BALLISTIC, ARAMID (06 FEB 2009) [SUPERSEDES MIL-C-44050A]

VPAM Standards:

VPAM APR 2006: Standards focused on bullet-resistant helmets, providing criteria for their design and ballistic resistance.

VPAM KDIW 2004: Specifications dedicated to vehicle armor, outlining the requirements for materials and designs used in armored vehicles.

VPAM BSW 2006: Sets criteria for ballistic body armor, detailing the performance standards for personal body armor.

VPAM HVN 2009: Guidelines for ballistic protection in civilian vehicles, focusing on the standards and methods for enhancing vehicle safety against ballistic threats.

VPAM PM Formerly VPAM PM 2007: General standards for ballistic materials and test methods, providing a comprehensive framework for assessing the performance of ballistic protection materials.

Other Standards

CAST Body Armour Standard 2017: Body Armour Standard CAST Publication number: 012/17

UL Standard 752: Bullet-Resisting Equipment

GOST Armor Standard (Russia): This standard applies to armor, designed to protect the trunk and limbs of a person (with the exception of the feet and hands) from cold and firearms, as well as the destruction of shrapnel

GA141 Armor Standard (China): The GA141 standard, as upheld by China's Ministry of Public Security, plays a vital role in defining the protective capabilities of police armor against ballistic threats specific to China.

STANAG 2920 NATO: Military standards for ballistic protection & armour, solutions for military applications are tested according to relevant NATO standards, normally STANAG 2920 (STANAG = NATO Standardization Agreement).

ISO/FDIS 14876-2: International body armor standard: DRAFT Withdrawn: specifies the performance requirements and test methods for determining the resistance of body armour to impacts by bullets from rifled weapons and to impacts by slugs from shotguns in repetitive single shot testing.

Note: The following standards are not published online so the following links are articles/support related to these standards. You should research and contact one of the NVLAP-accredited laboratories for additional information on these and other ballistic resistant and body armor testing standards.