ASTM E3347-25 Ballistic Shields: Oversight and Procurement

Published March 2025. Now, the Implementation Phase.

ASTM E3347/E3347M-25 was formally published in March 2025. With publication complete and verified models now appearing under independent certification programs, the standard has moved from committee development into operational implementation.

The technical framework is established.

The practical questions now are:

How should agencies interpret documentation?

What does third-party verification actually change?

How should procurement language adapt during transition?

What documentation must manufacturers now provide?

This discussion focuses exclusively on ballistic shields and reflects the post-publication clarity improvements emphasized by the committee: consistency between laboratories, clearer user documentation, improved marking requirements, and practical verification discipline.

This is an implementation discussion — not a marketing summary.

Visit the ASTM publication context for additional insights into the standard’s purpose.

Following this link for Independent verification context shows the currently active SEI dynamic listings.

Verification lists are dynamic. When reviewing, always check the current Verified Product Liststatus directly through the issuing verification body.

What ASTM E3347-25 Changes Structurally

ASTM E3347-25 introduces three operationally meaningful shifts:

System-level evaluation of the assembled shield

Expanded, structured shot distribution with edge and cluster requirements

Ongoing third-party verification with documentation and marking discipline

Each affects procurement defensibility and end-user understanding.

1. System-Level Evaluation

ASTM E3347-25 evaluates the shield in its intended-use configuration, including:

Ballistic panel

Viewport (if present)

Viewport interface and frame

Fasteners

Handles

Joints (including multi-panel designs)

Identified weak points

Areas of increased or reduced protection (e.g., ICW appliques)

This is a shift from purely material-focused evaluation under NIJ 0108.01.

Importantly, weak point evaluation applies to the entire assembled shield, including viewport-associated areas and interface components; angled impacts on viewport frames and associated hardware are not excluded.

This reinforces what the standard intends: evaluation of the shield as deployed, not just as manufactured.

2. Expanded Shot Distribution Philosophy

ASTM E3347-25 incorporates a structured shot distribution that includes:

Edge-zone impacts

Clustered impacts

Angled impacts

Distribution across the smallest and largest models

The emphasis is not simply on more impacts.

The emphasis is:

Consistent impact spacing

Defined shot-to-edge distances

Defined shot-to-shot distances

Repeatability between laboratories

Post-ballot refinements focused heavily on clarity to ensure lab-to-lab consistency. The objective is repeatable evaluation, not interpretive testing variation.

Agencies reviewing reports should confirm:

Declared shot-to-edge and shot-to-shot distances used in testing (not just that they exist).

How impacts were distributed across construction zones and across the smallest/largest models.

These are now required documentation elements.

3. Conditioning Sequence and Timing Discipline

Environmental conditioning is not new.

Timing discipline and sequence clarity are.

The standard includes defined conditioning sequences, including:

Thermal shock

Controlled ambient conditioning

Submersion

Extreme temperature exposure

Testing must begin no sooner than 5 minutes and no later than 10 minutes after removal from conditioning, with completion within 30 minutes.

Test documentation should clearly identify:

Conditioning sequence performed

Temperature and exposure durations

Time between removal and first impact

Whether reconditioning occurred if timing exceeded allowable limits

Conditioning sequence consistency was refined specifically to improve lab-to-lab repeatability.

4. Performance Requirements Beyond Penetration

ASTM E3347-25 requires that shields withstand required impacts without complete penetration.

Additionally, system-level performance expectations include continued functionality of critical components.

For example:

Handles must remain functional after impact so the shield can be repositioned in its intended mounting or use configuration.

This reinforces that the shield is evaluated as operational equipment, not simply a ballistic panel.

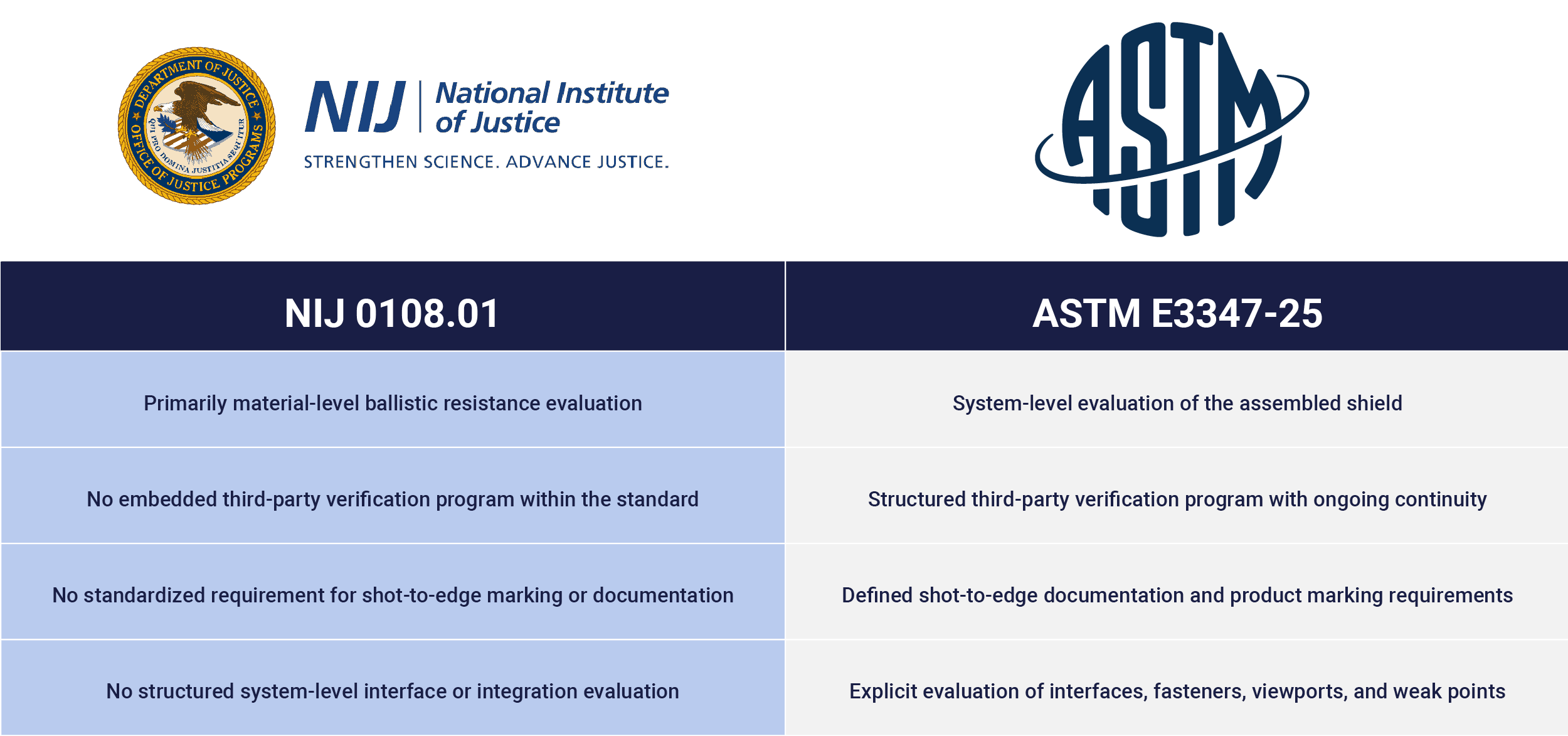

ASTM E3347-25 vs. NIJ 0108.01 — Structural Differences

This comparison must be precise.

Structural Differences of the NIJ 0108.01 and ASTM E3347-25 Standards

Both frameworks can produce effective shields.

The difference is in the documentation structure and oversight continuity.

Threat Classification and Mixed Labeling

Mixed labeling will persist during transition because agencies buy from multiple ecosystems. Treat the label as an index, not proof—then verify the threat matrix and conditioning sequence in the test record.

ASTM E3347-25 aligns shield protection levels to NIJ 0123.00 threat definitions.

Shield designations include:

ASTM-Shield-HG2

ASTM-Shield-RF1

ASTM-Shield-RF2

ASTM-Shield-RF3

ASTM-Shield-SG (optional shotgun addition)

During transition, agencies may encounter mixed labeling:

Level IIIA

Level III

HG2

RF1

RF2

During procurement evaluation, confirm:

Specific threat designation

Projectile type

Reference velocity

Whether the shotgun threat was included

Whether RF2 or RF3 levels introduce additional projectile characteristics that may affect shield weight and portability

Higher rifle-protection levels may increase shield mass and affect maneuverability and endurance during extended deployment. That tradeoff must be evaluated operationally.

Terminology alone is insufficient.

Threat matrix confirmation is essential.

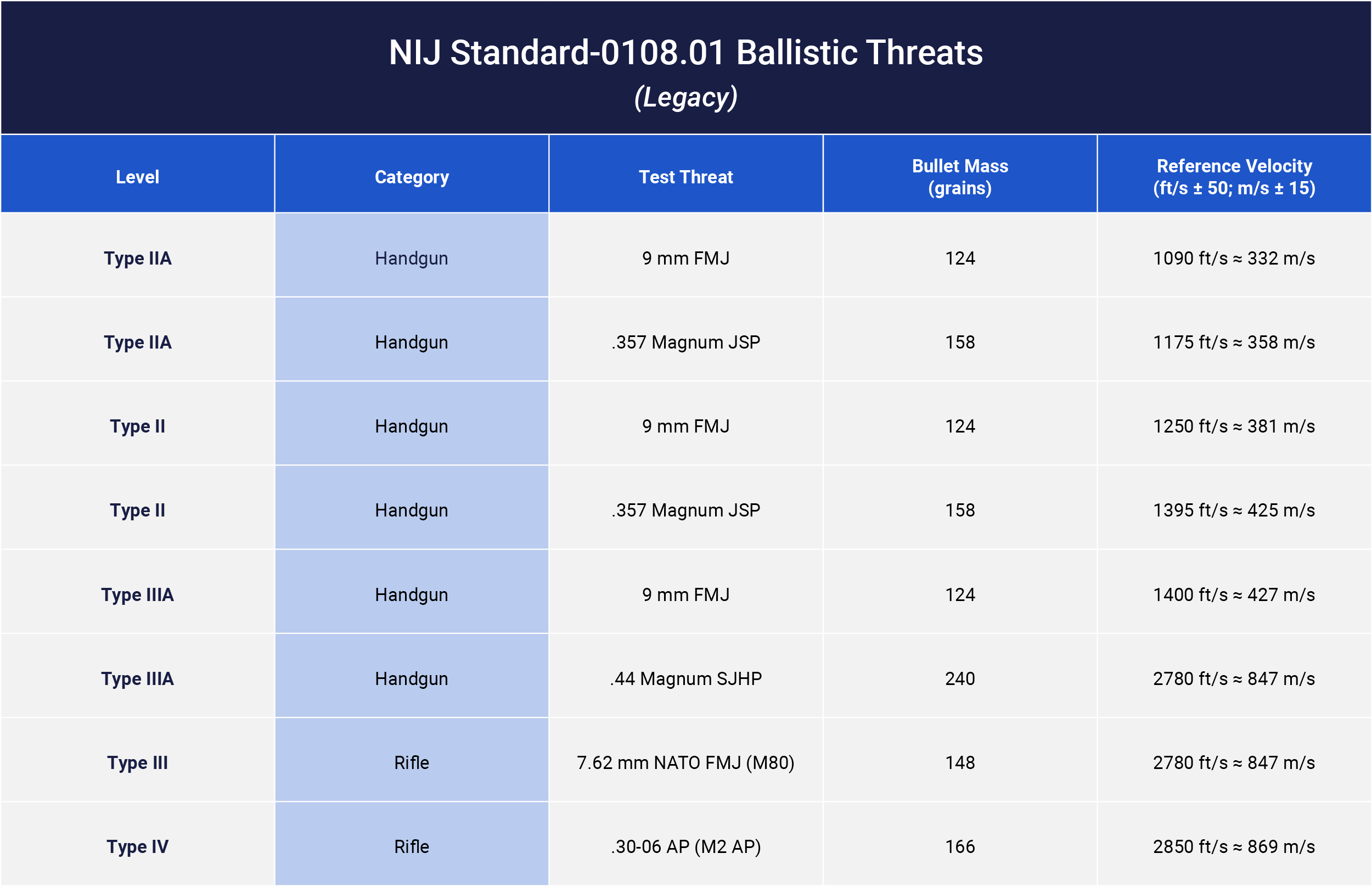

NIJ Standard-0108.01 Ballistic Threats (Legacy)

NIJ 0108.01 is a material-level ballistic resistance standard primarily intended for protective materials such as armor panels. For ballistic shields, agencies historically referenced handgun levels (e.g., Type IIA, II, IIIA) and rifle levels (Type III, IV). Below is a summary of commonly referenced NIJ 0108.01 threat designations historically applied to shield procurement, focusing on handgun and rifle categories. (Note: Type I is omitted as it's low-threat and rarely relevant for shields; velocities are nominal reference values with ± tolerances typically ±50 ft/s in testing.)

Key Notes on NIJ 0108.01:

Velocities shown are nominal reference velocities; NIJ 0108.01 testing allows ± tolerances (commonly ±50 ft/s).

Rifle threats under NIJ 0108.01 are tested at 15 ft (4.6 m).

NIJ 0108.01 evaluates ballistic resistance of protective materials; it does not prescribe structured multi-hit distribution, edge-zone testing, or assembled shield system integration requirements.

“Level IIIA” and “Level III” terminology commonly used in shield marketing derive from this material standard.

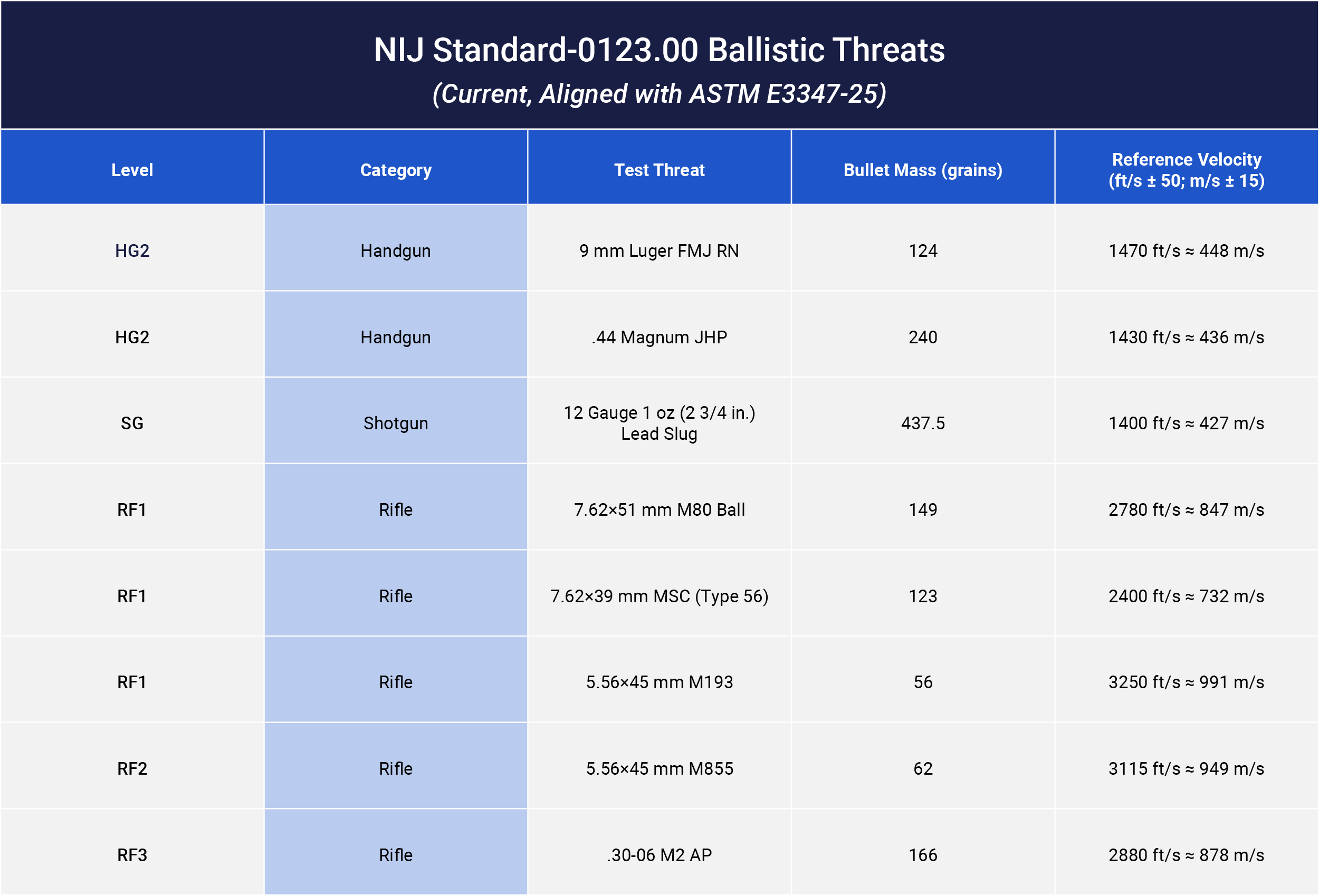

NIJ Standard-0123.00 Ballistic Threats (Current, Aligned with ASTM E3347-25)

NIJ 0123.00 defines modern threat levels used in ASTM E3347-25 for shields. It includes HG (handgun), RF (rifle), and SG (shotgun) levels. Below is a summary of relevant NIJ 0123.00 threat designations referenced by ASTM E3347-25 applied to shield procurement, including HG2, SG, RF1, RF2, and RF3. Data includes exact threats, masses, velocities (±30 ft/s tolerance typically), and notes from the standard (including Addendum #1 updates).

Key Notes on NIJ 0123.00

FMJ = Full Metal Jacket; RN = Round Nose; JHP = Jacketed Hollow Point; MSC = Mild Steel Core; BT = Boat Tail; AP = Armor Piercing.

Reference velocities shown are nominal test velocities. NIJ 0123.00 specifies a typical tolerance of ± 30 ft/s during testing.

HG2 is the primary handgun protection level referenced for ASTM E3347-25 shields.

SG is an optional shotgun add-on designation; it is not a standalone handgun or rifle level and may be paired with HG or RF shields.

RF levels are cumulative through RF2. RF2 includes all RF1 threats plus 5.56 mm M855. RF3 is a standalone armor-piercing rifle level.

Certain threats, including 7.62×39 mm MSC, are subject to additional consistency controls and audit procedures described within the standard.

NIJ 0123.00 replaced legacy threat structures used in prior NIJ standards and provides a consolidated, threat-based matrix now referenced by ASTM E3347-25.

Viewport Clarifications and Coupons

Viewport evaluation has received clarification through implementation bulletins and committee refinements.

Key points agencies should understand:

Viewport-associated areas may use different witness panel materials than opaque body portions.

Viewport coupons must reflect actual shield geometry, including defined horizontal and vertical distances from viewport edge to shield edge.

Weak point evaluation may include viewport frame areas.

Multiple viewport coupon configurations must reflect real-world construction, not arbitrary test shapes.

Test reports should include:

Photographs (front, back, mounting orientation)

Identification of viewport coupon dimensions

Identification of interface shots

Weight and dimensions of smallest and largest shields

Photographic documentation is now part of defensible reporting practice.

Product Documentation and Marking Requirements

ASTM E3347-25 significantly strengthens user-facing documentation.

Suppliers must provide:

Model designation

Serial number

Date of manufacture

Country of origin

Ballistic protection level

Shot-to-shot distance used during testing

Shot-to-edge distance used during testing

Warranty period

Products must include clear markings indicating:

Location of ICW appliques or increased protection

Areas of reduced or no ballistic protection (e.g., gun rests)

Shot-to-edge distance reference

These markings directly support user understanding in the field.

Procurement teams should verify that submitted models match the test basis and threat designation before comparing products across standards.

Procurement Drafting Considerations

Clear drafting reduces ambiguity.

If Requiring ASTM E3347-25

Agencies should specify:

Evaluation under ASTM E3347/E3347M-25

Current third-party verification status

Confirmation of conditioning sequence and timing compliance

Shot-to-shot and shot-to-edge distances

Required marking compliance

Test report photographs and weight/dimension disclosure

If Maintaining Legacy Frameworks

Agencies may require:

NIJ 0108.01 compliance

Equivalent system-level documentation

Multi-hit distribution disclosure

Edge-zone evaluation description

Environmental conditioning documentation

Clear threat matrix identification

The objective is documentation defensibility — not exclusivity.

Documentation Review: Verification Baseline

Before final acquisition decisions, confirm:

Standard referenced

Threat designation and velocity

Conditioning sequence and timing compliance

Shot-to-shot distance

Shot-to-edge distance

Identification of weak points and interface shots

Handle functionality verification

Test report photographs

Verification body listing status (current)

Verification listings are dynamic and subject to annual review.

Transition Reality

Implementation is progressive.

Some agencies will adopt immediately.

Others will observe early listings.

Legacy frameworks will coexist.

What changes now is not simply impact count; it is documentation clarity, marking discipline, laboratory consistency, and verification continuity.

That is the structural shift.

What does all of this mean?

ASTM E3347/E3347M-25 introduces:

System-level evaluation

Structured shot distribution

Conditioning sequence discipline

Post-impact functional expectations

Required documentation and product markings

Independent third-party verification continuity

The most meaningful shift is not the projectile. It is the documentation, marking, and verification structure surrounding it.

Agencies and manufacturers that understand that distinction will navigate this transition with clarity and defensibility.

IntelAlytic provides structured advisory to agencies and manufacturers evaluating shield programs under ASTM E3347-25 and legacy frameworks, focusing on documentation alignment, oversight analysis, and procurement defensibility.

The Armor List maintains reference visibility for verified shield models and their current verification status.

Modern standards require modern documentation.

Relevant References at the time of publication (Feb 2026)

1. ASTM E3347/E3347M-25 Official Standard Page(Purchase/Overview): Direct ASTM source for the published standard (March 2025 edition), including scope, significance, and abstract.

2. ASTM News: "Standards to Protect Those Who Protect Us" (January 2025): Official ASTM article on the protective equipment standards family, including E3347, verification program, and real-world intent—great for context on the "why" behind the shifts.

3. SEI Verified Products List (Dynamic/Current Page): SEI's main verification hub; links to the latest ASTM E3347 ballistic shields listing (PDFs update periodically—check for newest versions beyond the 2025-10 example).

4. NIJ Standard 0123.00: Specification for NIJ Ballistic Protection Levels and Associated Test Threats: Official NIJ page for 0123.00 (threat matrix referenced in E3347), including PDF download and explanation of HG/RF levels.

5. NIJ Standard 0108.01: Ballistic Resistant Protective Materials(Legacy Reference): The NIJ 0108.01 is a material-level ballistic resistance standard primarily intended for protective materials, useful for direct comparison to E3347's system-level approach.

6. SEI/ASTM Verification Program Overview(Related Press/Context): ASTM's 2023 announcement on the verification program (SEI-managed), covering E3347 shields, annual oversight, and marking—reinforces your "ongoing third-party verification" emphasis.